Toyota Improves the End-of-Life Process for Its Cars in Poland

Toyota strengthens its low-carbon strategy with the opening of a circular factory capable of processing 20,000 end-of-life vehicles per year.

Toyota Motor Europe announces a major new investment with the creation of a circular factory in Walbrzych, Poland. Covering an area of 25,000 m², this industrial site will process nearly 20,000 end-of-life vehicles each year. This initiative is fully aligned with the group’s carbon neutrality strategy and its ambition to develop a circular economy structured around the principles of the “3Rs”: reduce, reuse, recycle.

This new green factory will be the second for the manufacturer in Europe, following the opening of a first site in Burnaston, UK, in 2025. Drawing on this experience, Toyota aims to implement an industrial model capable of limiting the environmental impact of vehicles throughout their life cycle.

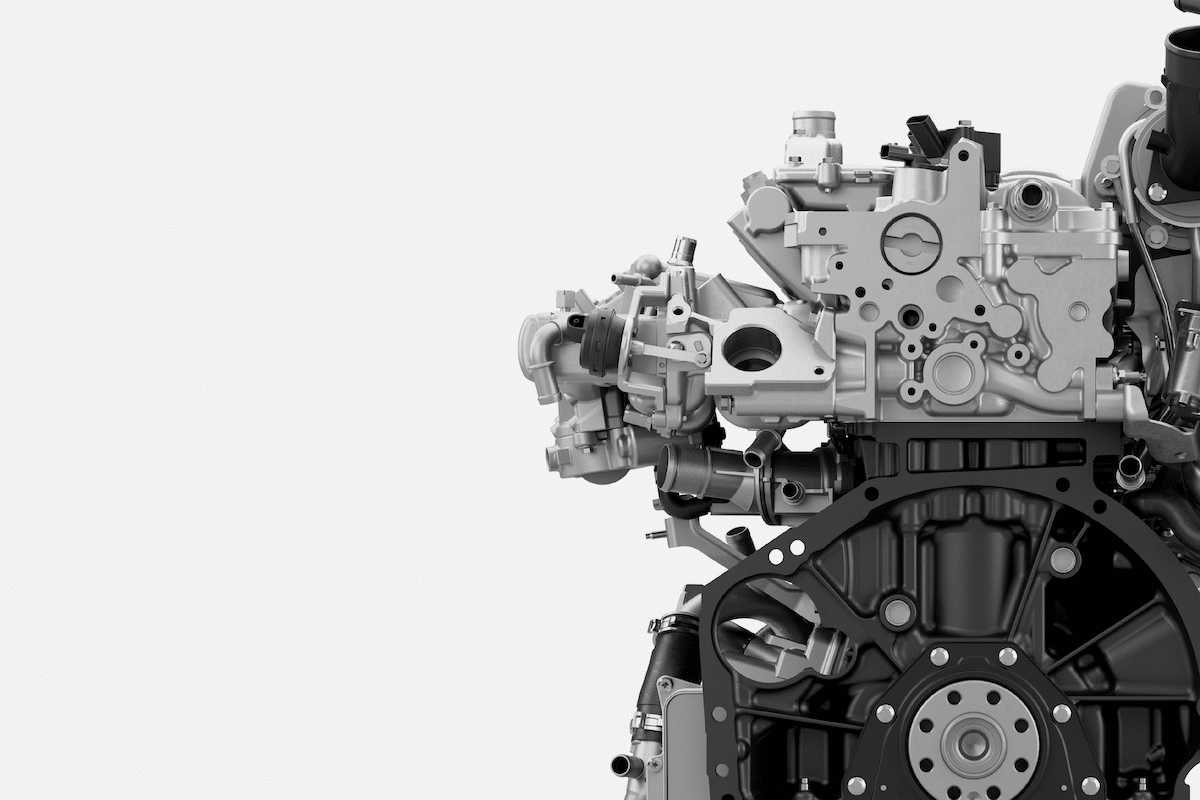

The Polish site will adopt a comprehensive approach to automotive recycling. Functional components will be recovered and refurbished where possible. Batteries, wheels, and technical parts will undergo specific evaluations to determine their potential for reuse. Strategic raw materials – copper, steel, aluminum, and plastics – will be extracted to be reintroduced into the production of new vehicles, thus reducing dependence on virgin resources.

You might be interestedin this article:

The factory will complement the existing industrial activities in Walbrzych, where Toyota produces key components for its thermal and hybrid powertrains. By focusing on circularity, Toyota Motor Europe aims to strengthen its European supply chain while reducing the carbon footprint associated with the extraction and processing of raw materials.

This page is translated from the original post "Toyota améliore la fin de vie de ses voitures en Pologne" in French.

We also suggestthese articles:

Also read