Batteries: Europe Scales Up

Volkswagen launches production of its first unified battery cells designed and manufactured in Europe.

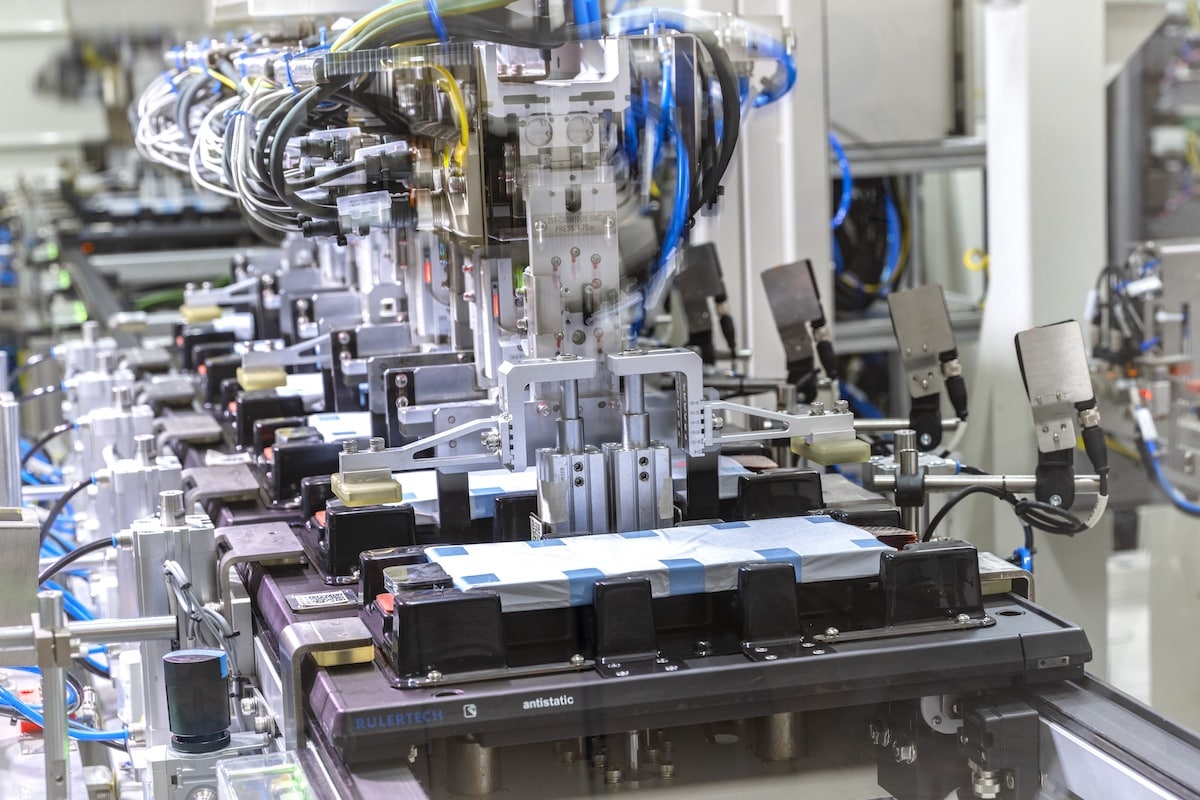

Battery cell production in Europe reaches a strategic milestone. In Salzgitter, Germany, PowerCo SE, a subsidiary of Volkswagen Group dedicated to batteries, has officially launched the manufacturing of its first “made in Europe” unified cells. This is a key step for the group, as well as for the European automotive industry, which thus strengthens its technological sovereignty in the face of intense global competition.

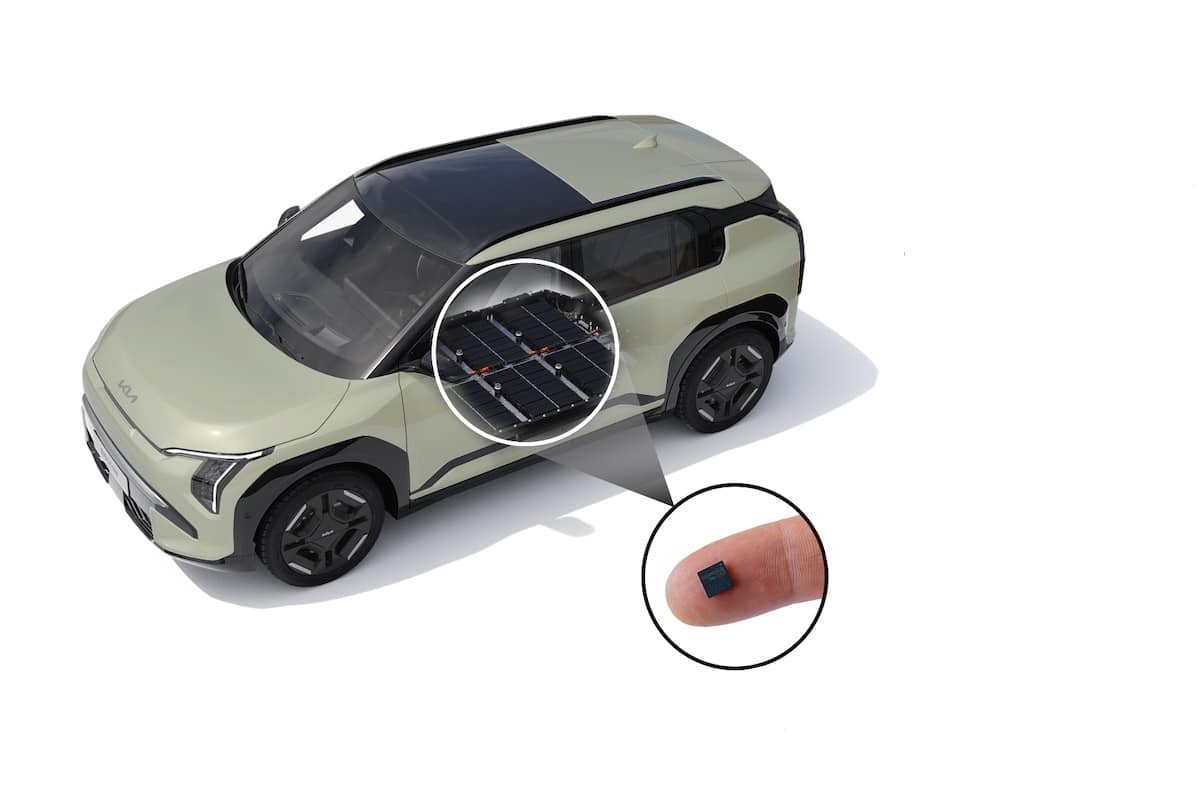

For the first time, battery cells are fully developed, industrialized, and produced on European soil by an automotive manufacturer. These cells will equip the future electric city cars of the “Electric Urban Car Family” from the Volkswagen, Skoda, and SEAT/CUPRA brands starting in 2026, following a testing phase currently conducted directly on vehicles.

Going Fast!

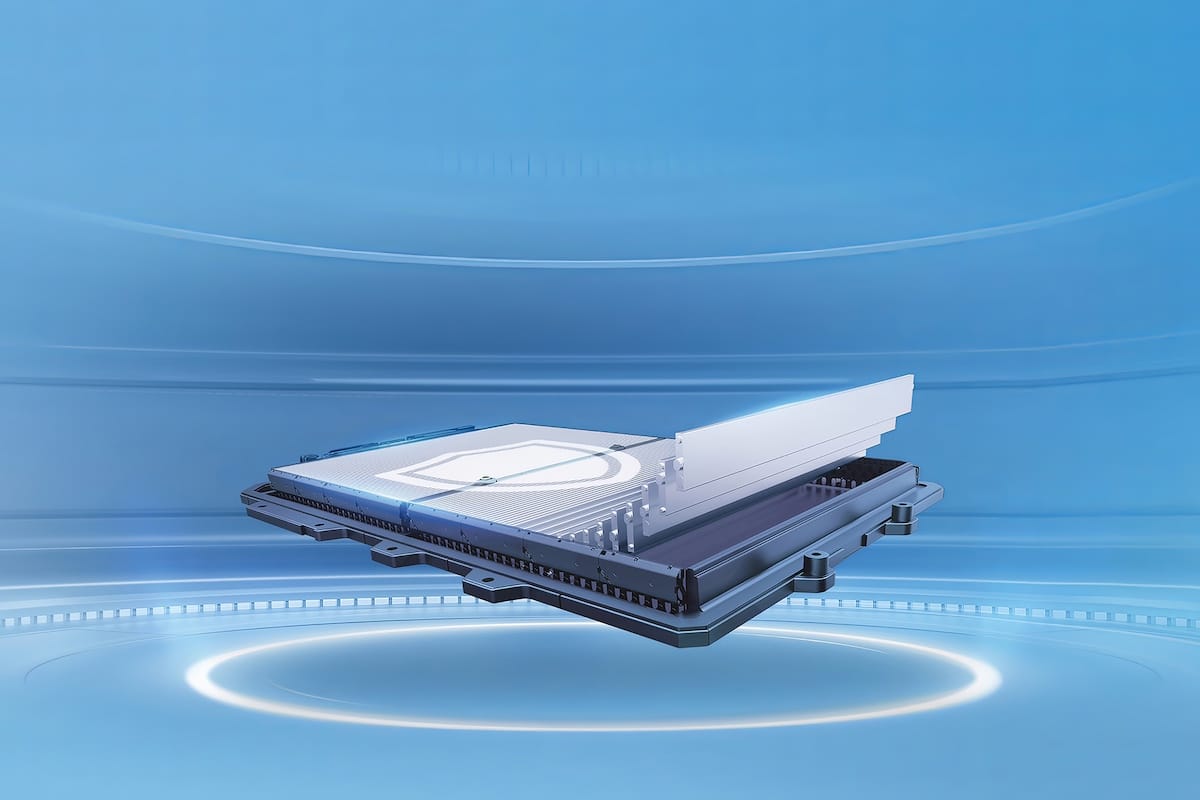

At the heart of this strategy, the PowerCo unified cell is based on a standardized architecture designed to be deployed at large scale across all brands and regions of the group. Compatible with different chemistries – NMC, LFP, and eventually solid-state materials – it allows for economies of scale while managing costs. The first version produced in Salzgitter, based on NMC chemistry, shows an energy density approximately 10% higher than current cells in the segment.

Volkswagen combines this cell with a new architecture known as “cell-to-pack,” removing intermediate modules to integrate cells directly into the battery pack. The benefits include increased range, efficiency, and performance, while simplifying design.

The gigafactory in Salzgitter will gradually ramp up production starting in 2026, with an initial capacity of 20 GWh per year, expandable to 40 GWh, equivalent to approximately 250,000 electric vehicles. The site already serves as a model for future PowerCo factories in Valencia, Spain, and Saint-Thomas, Canada.

Beyond the industrial aspect, Salzgitter aims to be a benchmark in sustainability and digitalization. Powered by renewable energies, the factory reduces its CO2 emissions by up to 115,000 tons per year compared to comparable sites. Advanced automation and real-time data analysis, supported by artificial intelligence, ensure traceability, quality, and efficiency of processes.

You might be interestedin this article:

With Salzgitter, Volkswagen clearly asserts its ambition: to master one of the key technologies of electromobility and position Europe as a central player in automotive battery production.

ALSO READ: BYD launches the revolution of solid-state batteries

This page is translated from the original post "Batteries : l’Europe passe à l’échelle" in French.

We also suggestthese articles:

Also read