What are the differences between NMC and LFP batteries?

To talk about autonomy, one must first understand the technologies. A brief overview of so-called Lithium batteries.

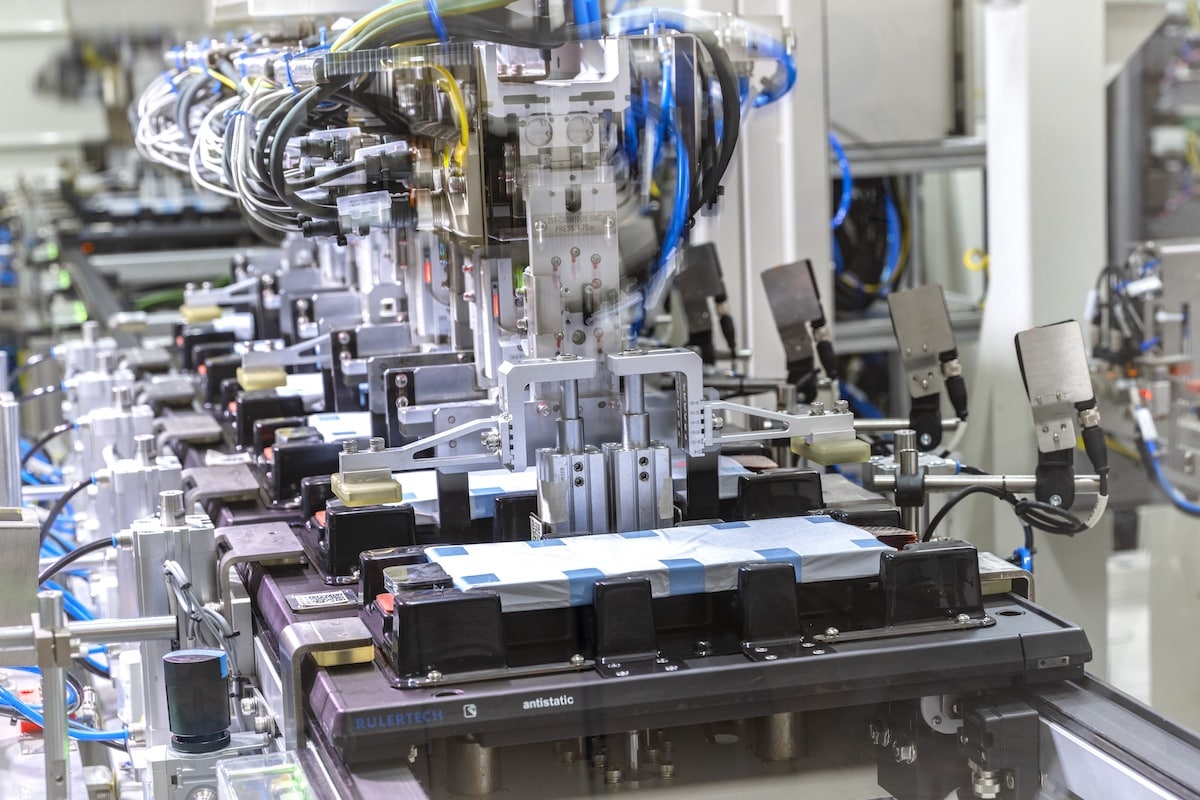

The automotive industry quickly chose to focus on lithium-ion batteries, whose manufacturing and operation are well mastered. Recently, the terms NMC and LFP have emerged, and these two types of batteries are competing for dominance. But what are their advantages and disadvantages ?

First of all, LFP and NMC are not strictly speaking divergent technical solutions, but rather two subclasses of lithium-ion batteries. LFP uses lithium phosphate, iron, and phosphorus as cathode material, while NMC uses nickel, manganese, and cobalt.

Most electric vehicles have long used NMC batteries, but these are increasingly criticized. Above all, nickel and cobalt are primarily mined in Russia and Congo. Sanctions against Russia and dubious labor practices in Congo push the industry to seek alternatives. Secondly, NMC batteries are sensitive to thermal runaway, which can lead to violent fires. Finally, with a lifespan of about 1000 cycles, NMC batteries will need to be replaced every ten years or so, roughly half of the theoretical lifespan of an electric vehicle.

LFP batteries exhibit higher weight for equal performance. This disadvantage has so far relegated them to entry-level electric vehicles, as their production cost is generally lower due to a broader availability of raw materials worldwide. Finally, LFP batteries are known to suffer from poor charging performance at very low temperatures. The widespread adoption of heat pumps has completely mitigated this issue.

The shift to LFP battery technology has therefore taken place

First of all, let’s remember that LFP batteries have a longer lifespan than NMC batteries. They offer nearly five times more charge cycles than NMC and provide higher round-trip efficiency. LFPs also experience less degradation than NMC at higher temperatures and at faster charge and discharge rates. This means that LFPs are better suited for high-performance driving and… fast charging ! And it’s this last point that gives them all their appeal !

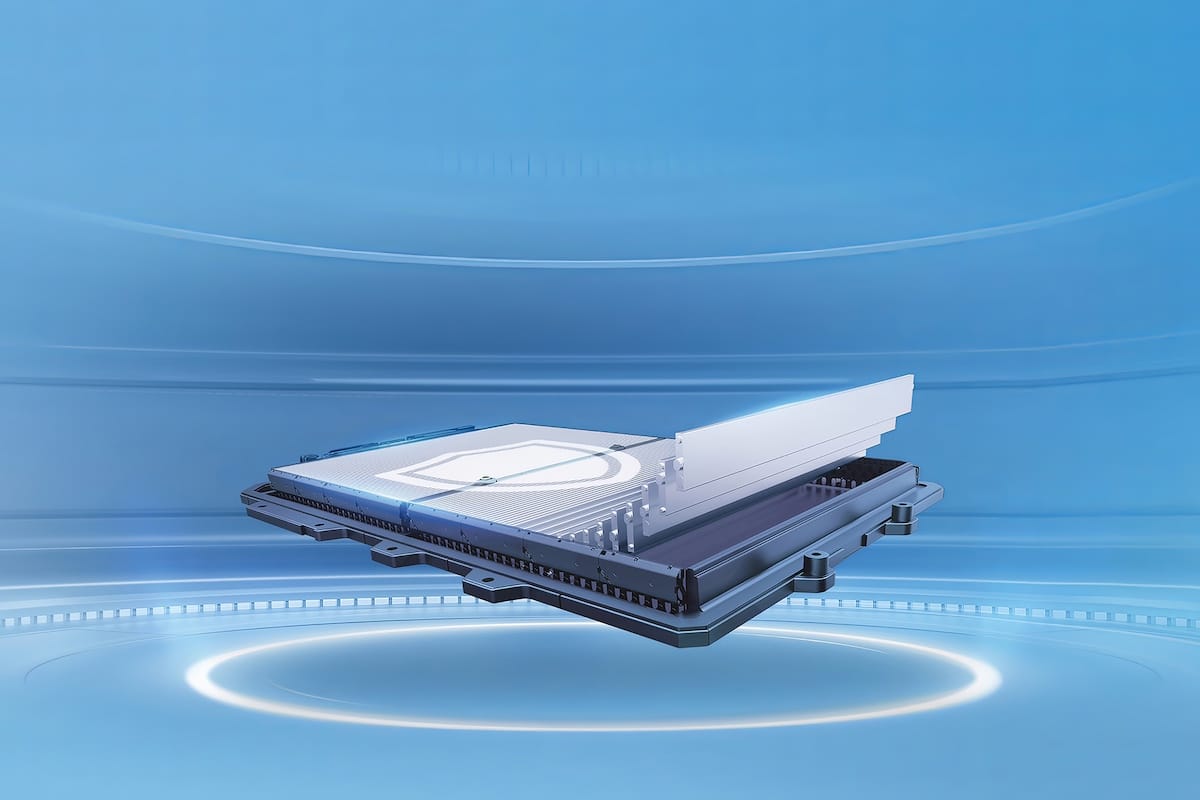

Faster recharges lessen the interest in a very high-capacity battery. No reasonable driver will travel 1,000 km without stopping, and if it becomes possible to recover 300 km of range in a few minutes, let’s say during a scheduled bathroom break, one can cover a very long distance without spending hours watching their car charge. Less autonomy but smaller batteries and logically lighter. Moreover, we now know how to use the battery pack as a structural element of the chassis, allowing us to do away with the use of a container. More weight savings.

Thus, today it is possible to develop a car with a more than reasonable range using fast-charging LFP batteries without excessively burdening the vehicle.

NMC is likely to remain the standard in luxury vehicles for which range is a significant commercial argument. Meanwhile, electric vehicle manufacturers continue to reduce vehicle weight and improve efficiency, with the energy density of LFPs expected to become more widespread in lower-end segments.

This page is translated from the original post "Quelles sont les différences entre les batteries NMC et LFP ?" in French.

We also suggestthese articles:

Also read