SEAT and CUPRA Crash Into the Future

SEAT and CUPRA launch a state-of-the-art press, symbolizing a faster, connected factory ready for the electric era.

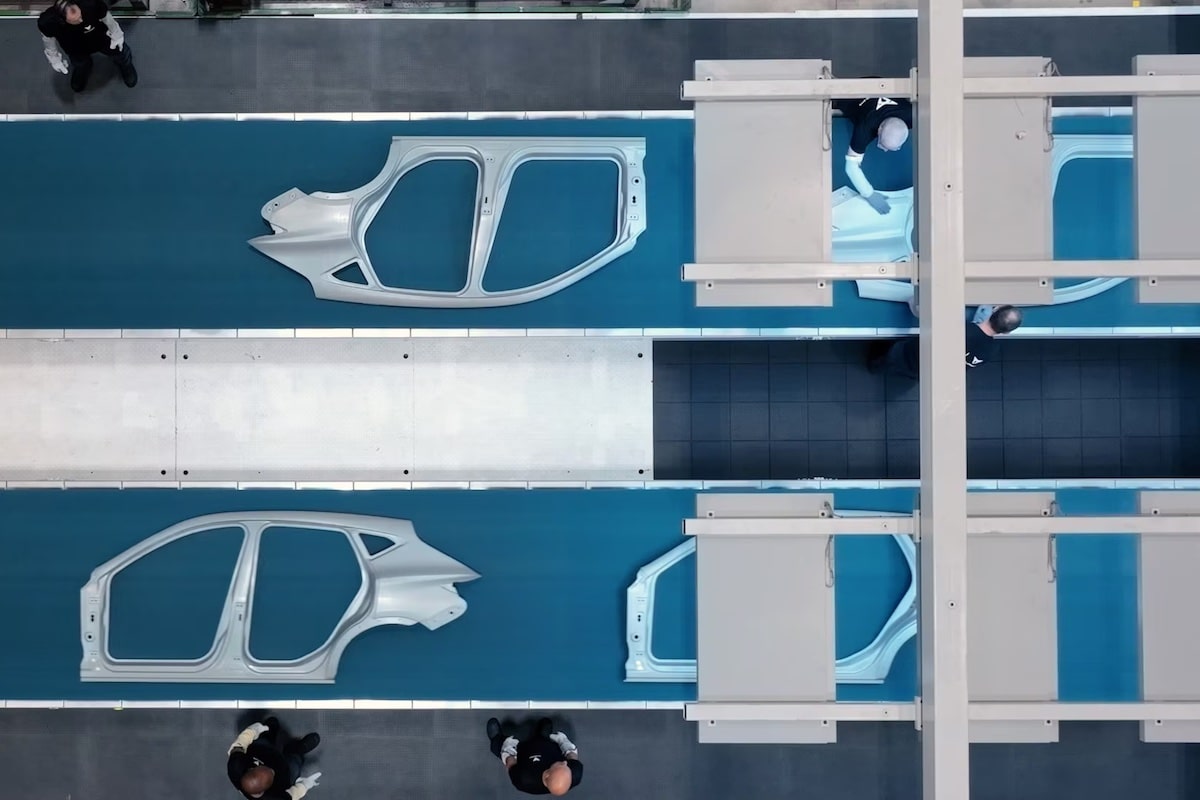

In Martorell, the industrial heart of SEAT and CUPRA beats stronger than ever. After forty months of design, engineering, and colossal work, the new PXL press has been put into operation. A true steel monster, it can stamp up to four million parts per year, a pace worthy of the new electric era the group is turning towards.

This colossal machine is not just powerful: it is also fearsomely efficient. Capable of 15 strikes per minute, it shapes body panels at record speed. Its secret? The advanced automation of die changes, now reduced to five minutes instead of several tens previously. Result: up to fifteen daily configurations to manufacture different parts without interrupting the pace.

A big, strong baby

But behind the industrial performance lies a true engineering feat. To absorb the phenomenal force of 81,000 kN, the press rests on a nine-meter deep pit and on twenty-meter concrete piles, equivalent to a seven-story building. An extraordinary infrastructure, made possible by the precise coordination of technical and logistics teams.

The innovation does not stop there. Each stamped part generates nearly 3,000 data points, feeding an advanced analysis system. The goal: to anticipate maintenance needs and refine production processes through prediction.

You might be interestedin this article:

To support this revolution, the Martorell teams have been trained in these new technologies. “We have changed our mindset: we are ready for the electric era,” says Jose Arreche, factory director. In Martorell, sheet metal now bends to the future.

ALSO TO READ: CUPRA gives a final dance to a legendary engine

This page is translated from the original post "SEAT et CUPRA emboutissent le futur" in French.

We also suggestthese articles:

Also read