Renault and the Future of Electric Motors

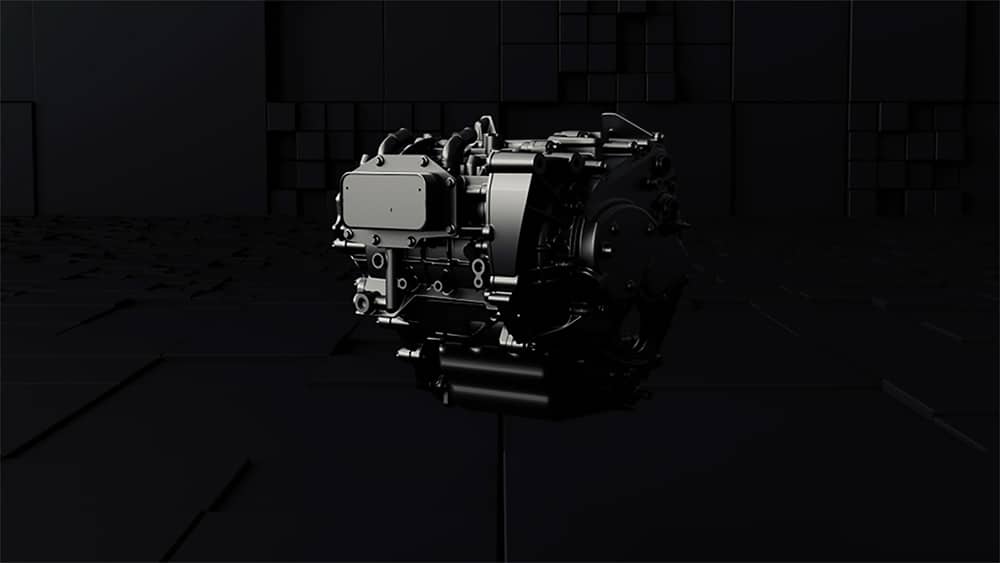

Still in the prototyping phase, this next-generation electric motor developed by Renault and Valeo, called E7A, will be launched in 2027.

An innovation made in France for a more powerful, more compact, and cleaner motor. Renault Group and Valeo combined their respective expertise to create a new generation. Thanks to regular exchanges between the automaker and the automotive supplier, this partnership launched in 2021 quickly evolved into co-development. Each brought its key component (the rotor for Renault Group and the stator for Valeo) and their technological development and production expertise. The development of this high-tech electric motor, named E7A, is currently underway.

Without Rare Earth Elements, a More Environmentally Friendly Electric Motor

Renault is a pioneer and leader in the production of electrical synchronous units with wound rotors (EESM technology, for Electrically Excited Synchronous Motor), launched in mass production with ZOE in 2012. Its expertise lies in delivering an architecture for this new E7A electric motor that is “all-in-one,” making it 30% more compact at the same power as the current motors used in Mégane E-Tech Electric and Scénic E-Tech Electric. Additionally, it features a rotor technology free of rare earth elements, reducing its carbon impact by 30%. By favoring the wound rotor over permanent magnet electric motor technology, Renault offers better efficiency, secures its supply chain, and maintains independence from rare earth-producing countries and magnet suppliers.

More Power and Efficiency

This third-generation electric motor will also help reduce the battery recharge time since the system voltage will be increased to 800 volts, compared to the current standard of 400 volts. It will be both powerful and efficient, thanks to the stator supplied by Valeo. The new E7A electric motor will thus develop up to 200 kW: more power without needing to use more electrical energy. Finally, this motor uses Hairpin technology for copper wire assembly, a specialty of Valeo since 2010.

At this stage, this motor is still in the development phase. Several more steps are needed before it can enter mass production. Large-scale production of this next-generation motor is scheduled to begin at the Renault Group plant in Cléon in late 2027.

READ ALSO > Kardian, Renault’s International SUV

This page is translated from the original post "Renault et le moteur électrique du futur" in French.

We also suggestthese articles:

Also read