Car Brake Pollution: A French Startup’s Solution

Harmful particles emitted by cars do not come only from the exhaust. Brakes are also a significant source. A French startup offers a solution.

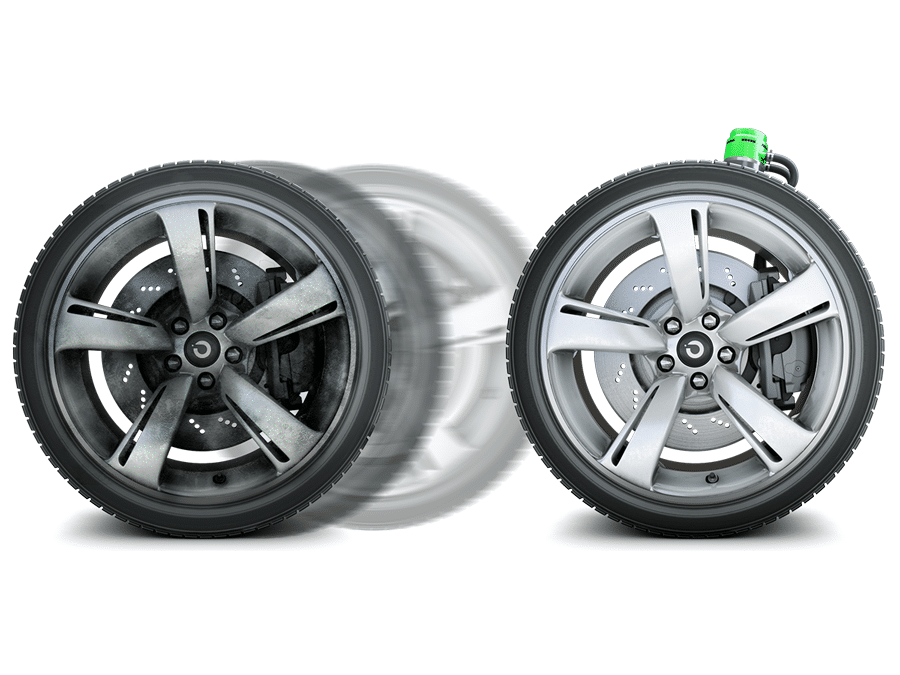

Installing a mini-suction system to capture micro-particles from braking, that’s the idea developed by Tallano. According to the French engineering startup, only 450 brakeings — less than two days of a Parisian taxi’s activity — are needed to blacken the filter, which was pristine white the day before. This suction system, called Tamic (turbine for micro-particle aspiration), aims to change the game. This small turbine can capture over 90% of dust particles from braking, without affecting slowing or fuel consumption. This device has already been tested for a year on the Paris RER line C.

This solution works like a vacuum cleaner, with a small electric motor for suction and a filter to trap particles. The front aspiration component is integrated under the engine hood, so it does not add to the unsprung mass, and the whole system is protected from gravel and moisture. The secret to its operation lies in the modified shape of the brake pads, which are grooved to capture particles. Thus, aspiration occurs at the source, at the moment when the pad contacts the disc. An electronic control system is dedicated to manage it. It can, once the vehicle is stopped, continue to suck in order to absorb the remaining particles.

Tallano works with manufacturers and equipment suppliers to equip production cars with this technology as a first installation. An evolution of regulations is underway with the upcoming Euro 7 standard. This will take into account brake emissions, with the goal of reducing them by between 85 and 90%. For electric cars, although braking is managed differently with regenerative braking, there is still a conventional component that also requires post-treatment.

Other methods to reduce brake-emitted particles are being studied, such as new materials for the brake pad/disc pair. 2024 is expected to be the year when series production of this type of solution begins for early adopters. This same year, the system is also scheduled to debut on racing circuits as part of a partnership between Tallano and Mission H24, the hydrogen prototype that will race at the 24 Hours of Le Mans in 2024 aiming for zero emissions.

An Unrecognized Pollution

Brake dust is visible to the naked eye, with black marks on the rims of the front wheels (where braking is most intense). Its danger is maximized when dispersed. “It’s a problem both health and environmental-wise,” explains Jean-Louis Juchault, CEO of Tallano. The dust consists of small, volatile, irritating, toxic, or even carcinogenic particles that can affect the lungs, as well as larger and heavier particles carried into stormwater runoff. “We are the only ones reducing emissions both in particle count and in mass.” According to Tallano, their emissions are up to six times higher than particles from exhaust fumes, up to 30 mg/km for a passenger car.

Such systems require filter replacements at the same interval as regular maintenance, every 30,000 km. But then what to do with the captured particles? A recycling process needs to be developed. Unlike gasoline and diesel particulate filters (DPFs), the particles are not burned off during regeneration cycles. There is still a long way to go before mastering all pollutants emitted during driving.

Another source that must be addressed is particulate production by tires. But one step at a time…

This page is translated from the original post "Pollution des freins de voiture : la solution d’une startup française" in French.

We also suggestthese articles:

Also read