Stellantis entrusts Orano with its battery recycling

Cobalt, nickel, and lithium revalorization support Stellantis’ approach to the circular economy.

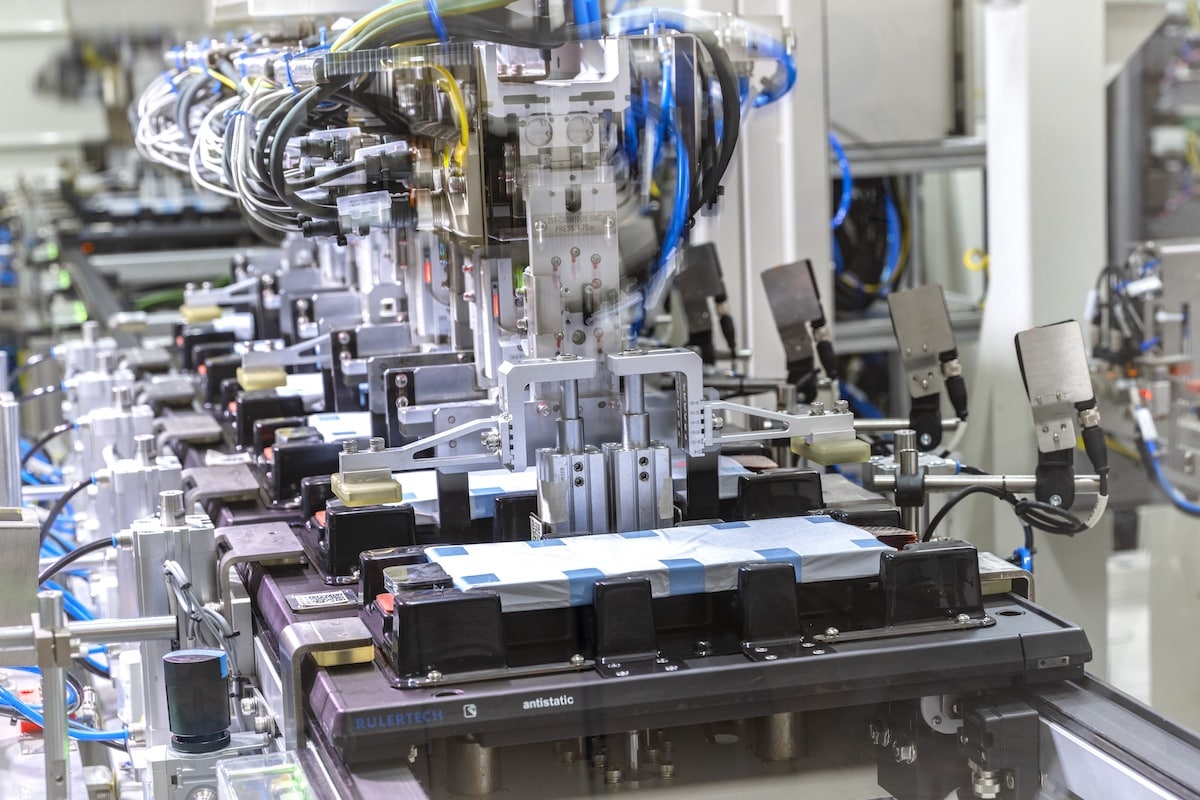

Stellantis and Orano announce today the signing of a memorandum of understanding aimed at creating a joint venture specializing in recycling end-of-life vehicle batteries and production waste from gigafactories in Extended Europe and North America.

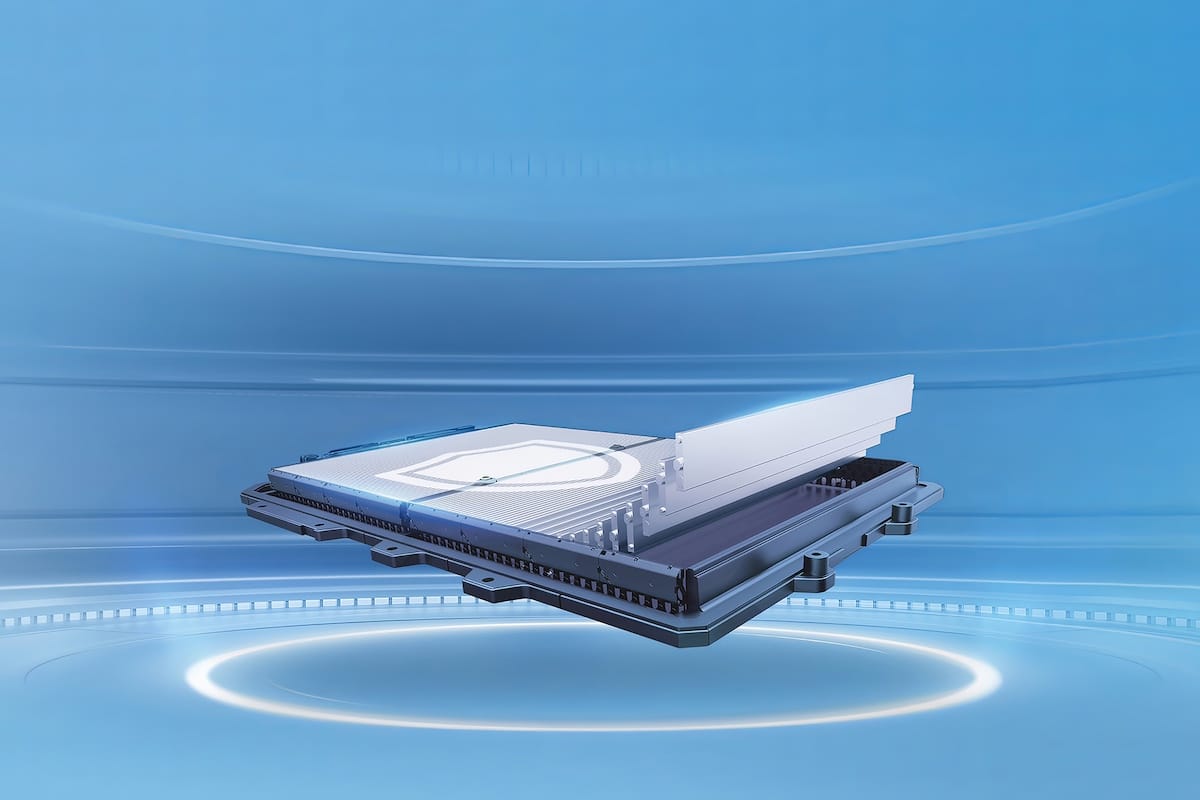

The joint venture is based on an innovative low-carbon emitting process developed by Orano, breaking with existing methods. It allows, on one hand, the recovery of all components of lithium-ion batteries, and on the other hand, the production of new materials for cathodes. This joint venture will also produce materials known as “black mass” or “active material.” The obtained mass can be refined in the future at Orano’s hydrometallurgical site planned for Dunkirk, France, then reused in batteries, thus closing the circular economy loop.

Thanks to this innovative approach to preprocessing and Orano’s cutting-edge hydrometallurgical technology, metal recovery rates can reach exceptional levels above 90%. This will enable equipment manufacturers to meet the recycling rates recommended by the European Commission for electric vehicle batteries while ensuring the sustainability of their economic model. In a context of increasing demand for strategic metals and Europe’s high dependency on these metals, Orano positions itself as a key player in the integrated value chain, from battery recycling to cathode material production.

ALSO READ > Peugeot, Opel, Citroën and Fiat renew their utility vehicle ranges

This page is translated from the original post "Stellantis confie à Orano le recyclage de ses batteries" in French.

We also suggestthese articles:

Also read