Lithium: a battery factory in Alsace starting in 2025

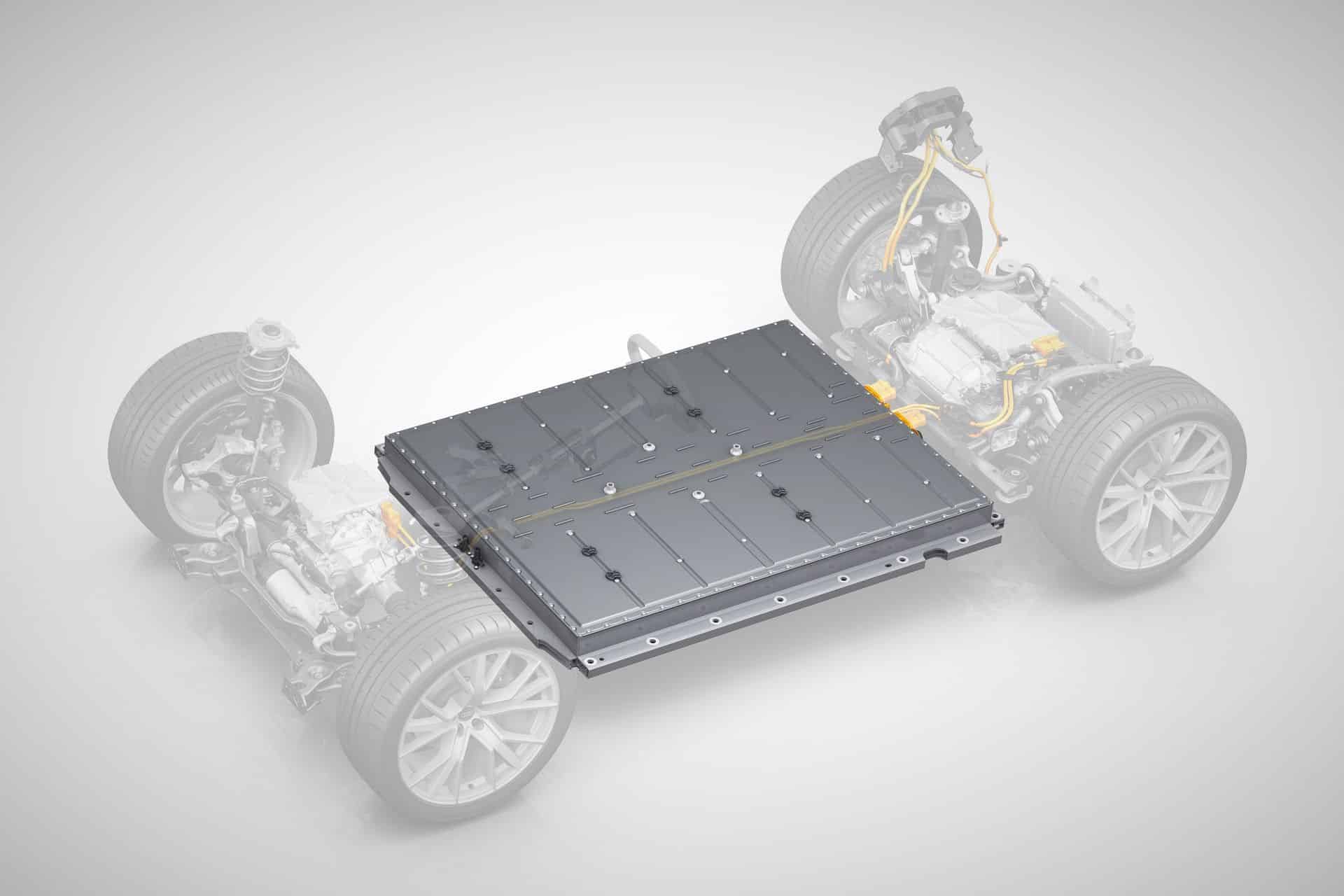

Viridian Lithium will open the first French lithium plant for batteries in Alsace, capable of powering up to 2 million vehicles per year.

Lithium is the gold of the 21st century. Essential for powering the batteries of our electric devices, including cars and trucks. However, Europe (and France) imports almost all of this metal. It is primarily mined in Australia, China, Chile, and Argentina.

Yet, our continent and our country are rich in deposits. But local populations – and Europeans in general – oppose lithium mines on their territory. Nevertheless, numerous projects are underway, with the first in France scheduled for 2025.

Powering 2 million electric vehicles per year

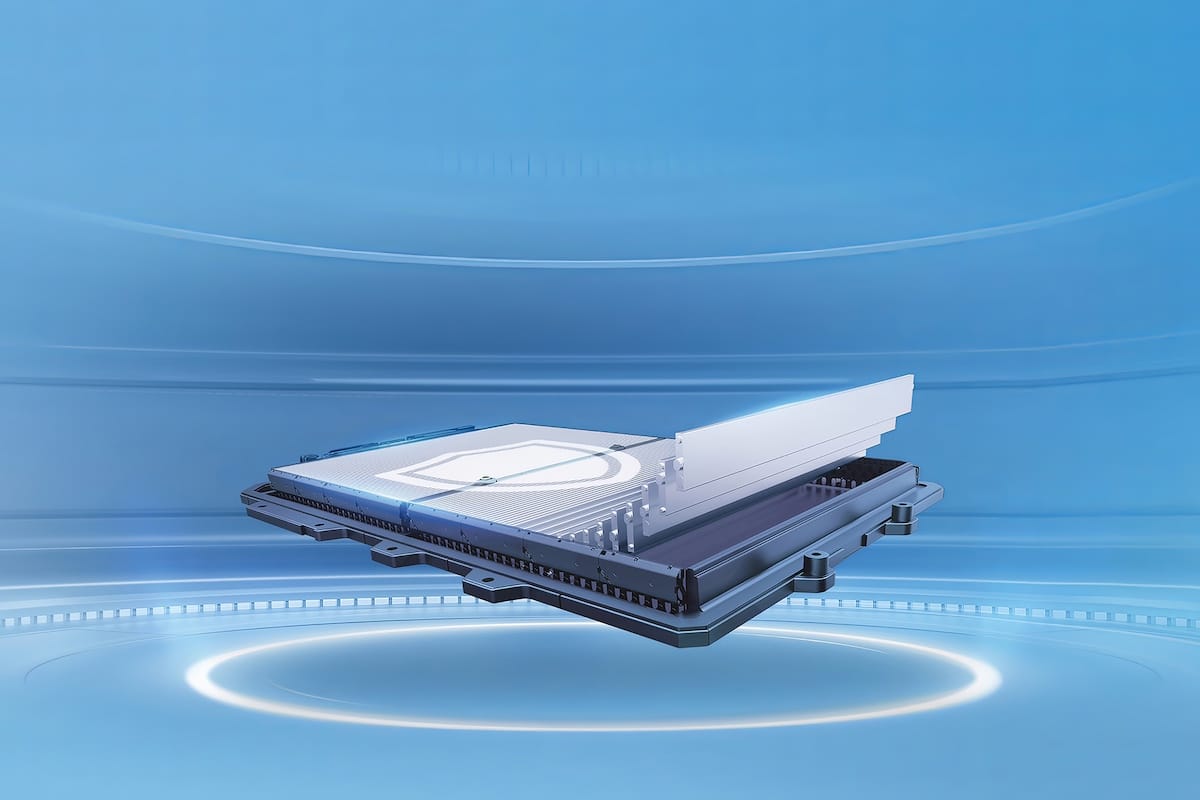

Viridian Lithium has announced its intention to produce this material for batteries. The site will be located in Lauterbourg (Bas-Rhin), spanning 20 hectares. The goal is to produce 25,000 tonnes of lithium hydroxide initially, then 100,000 tonnes by 2030.

This amounts to batteries for two million vehicles. For comparison, the French new car market totaled 1.66 million units in 2021. The project is expected to create 250 direct jobs and 600 indirect jobs.

“We are very proud to announce the launch of this unique project in France, at the heart of Europe, in the Grand Est region,” states Rémy Welschinger, president of Viridian Lithium, “our expertise in lithium production methods as well as the dynamism […] will enable us to facilitate the transition to electric mobility in Europe and meet the European Commission’s zero-carbon ambitions.”

A low-carbon lithium?

The company also claims that its material “will have the lowest carbon footprint in the world”. This will be achieved thanks to the “French energy mix”, which is 70% nuclear and has a steadily increasing share of renewables – wind, solar, and hydroelectric. Another way to reduce environmental impact is through the refining methods used for extracted salts. Veridian Lithium states that it ensures “innovative chemical purification and conversion processes”.

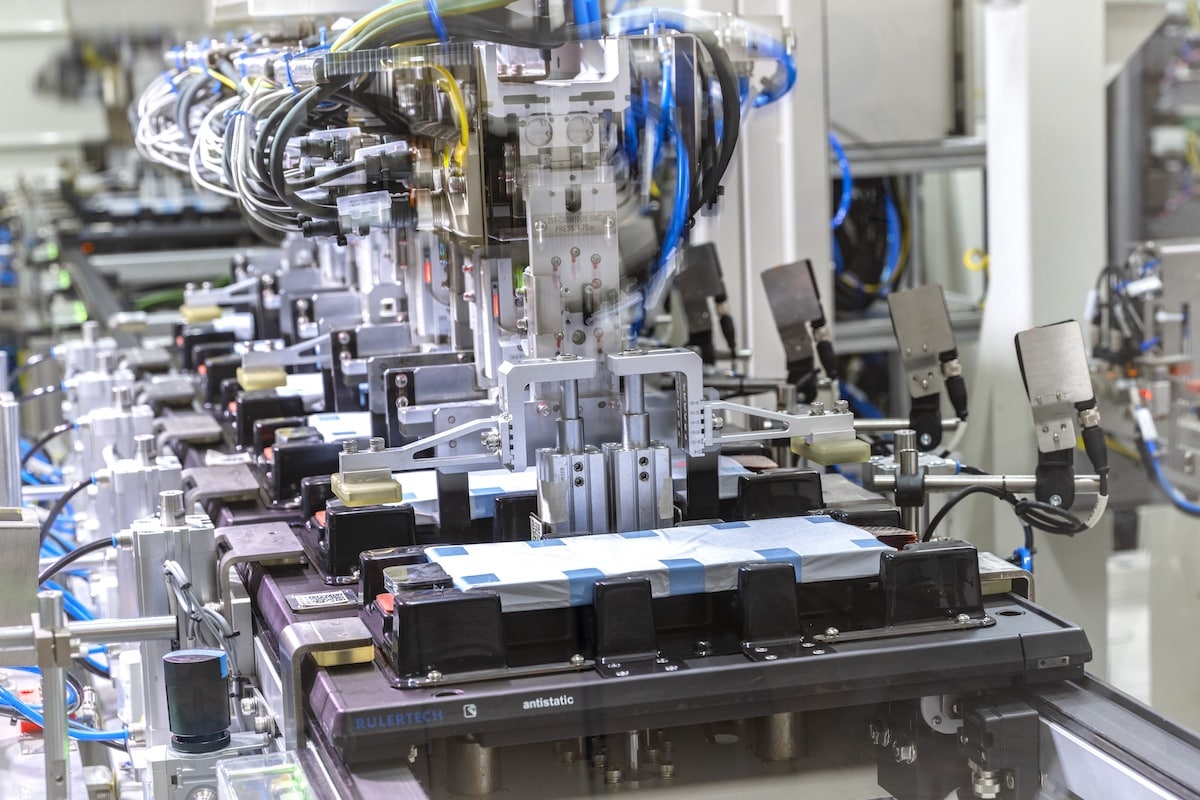

To ensure its future site, Viridian Lithium has partnered with Technip Energies for engineering, Veolia for lithium refining and purification, and CEA Liten to test the final product – lithium hydroxide – in batteries.

The plant is therefore set to deliver the first French “battery-grade” lithium in 2025.

Read also: Can electric car batteries be recycled?

This page is translated from the original post "Lithium : une usine pour batteries en Alsace dès 2025" in French.

We also suggestthese articles:

Also read