Automobile Battery Recycling: A Sector in France by 2030?

The France 2030 investment plan now has two valiant warriors in the field of electric vehicle battery recycling.

Two new battery recycling facilities will soon be established as part of the France 2030 investment plan, according to a government announcement.

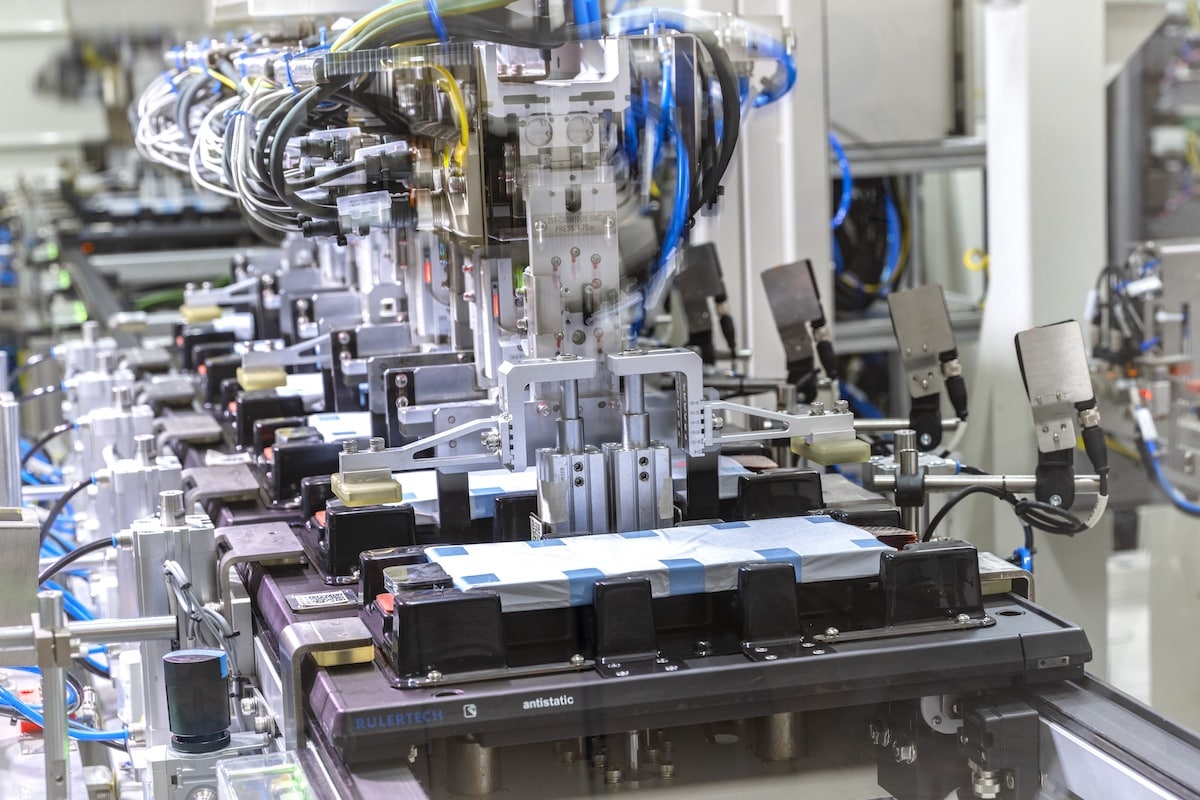

The trio formed by Veolia, Solvay, and Renault, along with the duo Mecaware-Verkor, are the two chosen entities. They dominate two different areas of recycling at their facilities in Dieuze (Veolia) and Dunkirk (Verkor). The rare and precious metals from automobile batteries, notably lithium, essential for electric vehicle batteries, will be recycled there.

The French government will invest approximately 30 million euros in addition to the existing France Relance project.

How does this concern me?

The recycling of electric vehicle batteries is part of the government’s measures to strengthen its investments in what it calls key sectors.

Precious metals and rare earth elements are important components of our daily lives, and some of our electronic devices contain them. Our smartphones and other so-called “connected” devices consist of chips containing rare and/or precious metals.

This is also better for the environment and for our wallets. Components for new vehicles will have to travel less far. Local production will enable automakers to address the shortage of components more quickly, thus easing the market for new cars.

An increase in the recycling rate of automotive batteries will thus lead to the relocalization of the production of elements requiring rare and precious metals in Europe.

What real impact can battery recycling have?

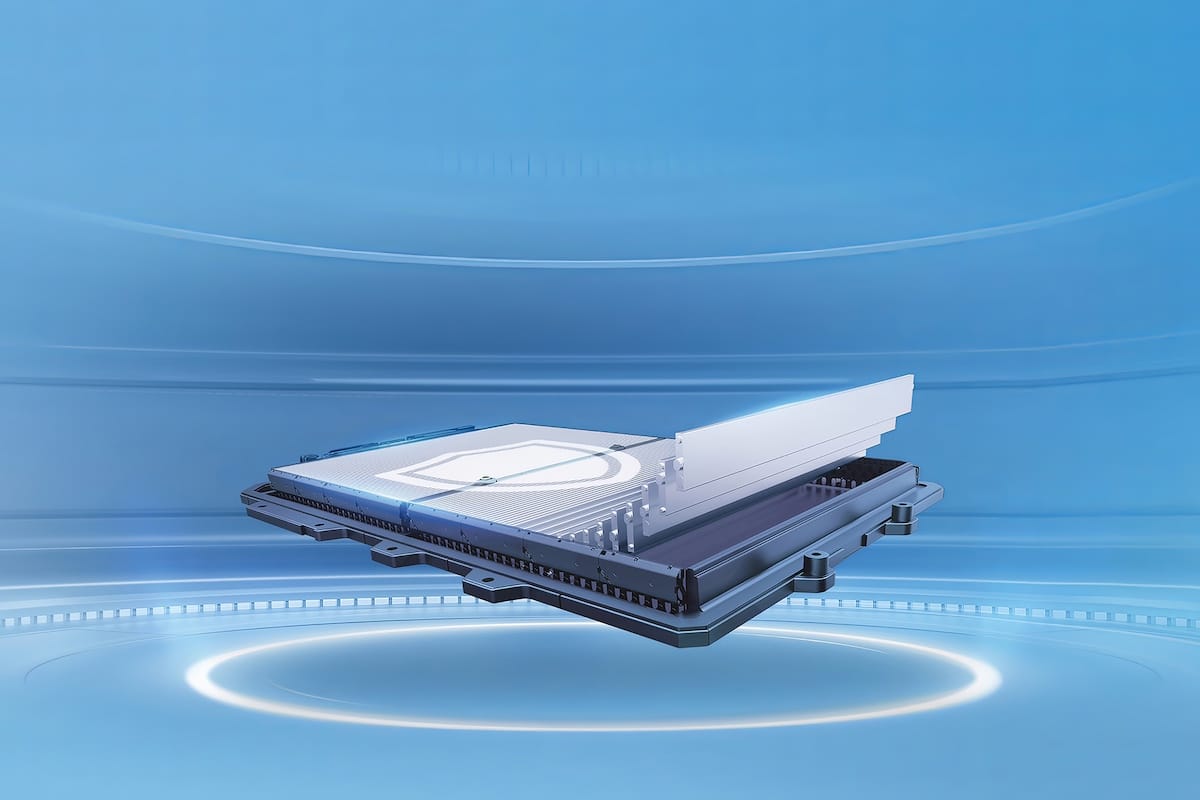

Recovered electric vehicle batteries can be reused in other industries. Batteries that are too damaged to be used in another electric vehicle can be dismantled to sell or recover the metals inside. The supply of lithium has become complicated following the COVID-19 crisis. This metal is used in the composition of lithium-ion batteries, which are found in our phones or laptops.

Furthermore, a directive imposed by European legislation mandates “the inclusion of recycled raw materials” in the production of new batteries starting in 2025. Minimum thresholds for cobalt, lithium, and nickel will be set from 2030. Could this encourage LFP batteries (lithium-iron-phosphate)? Despite the government’s investment in recycling automotive batteries in France, this is likely to account for only a small percentage of the market for rare and precious metals.

Read also: Mercedes-Benz aims for near-complete recycling of batteries

This page is translated from the original post "Recyclage des batteries automobiles : une filière en France pour 2030 ?" in French.

We also suggestthese articles:

Also read