Fifteen and GCK, Players in Reindustrialization

Fifteen and GCK Battery have designed a new battery that will soon enter production in Lempdes, Puy-de-Dôme.

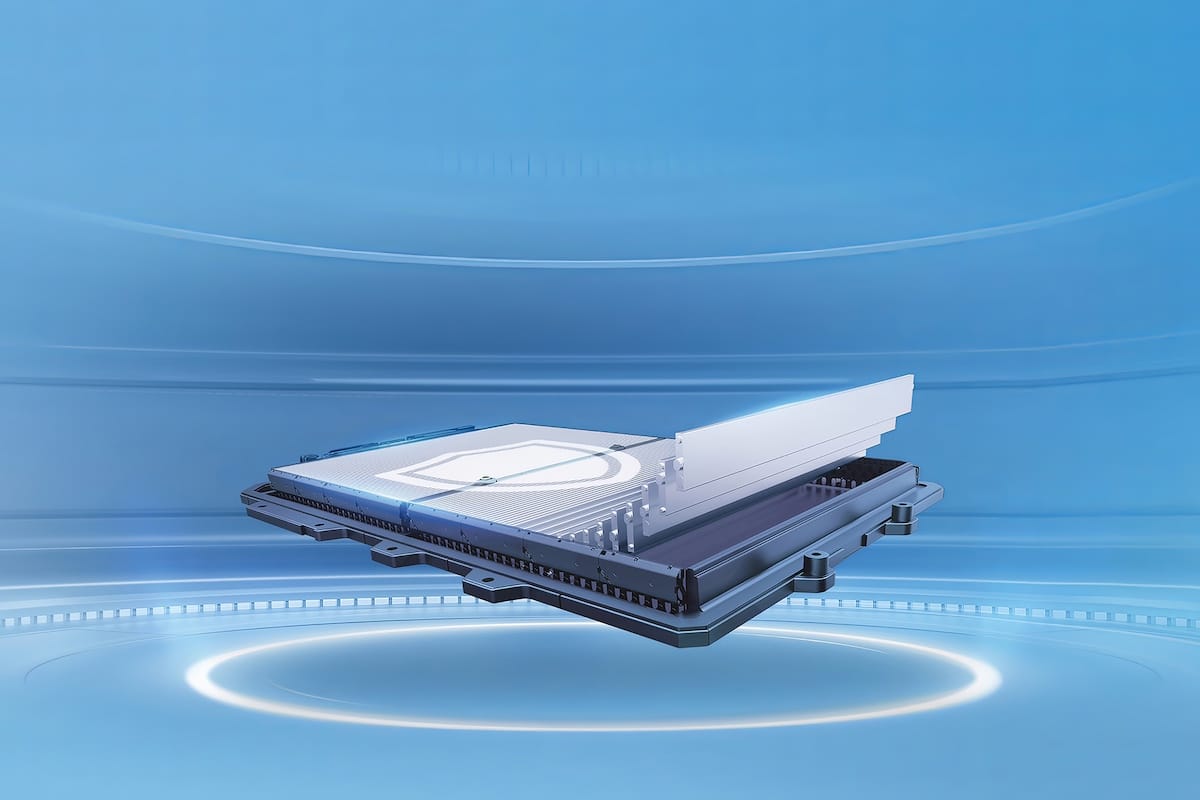

The new battery model developed by Fifteen and GCK Battery offers doubled lifespan (in number of charge cycles) thanks to an optimized design, increased reparability, and reduced energy consumption in standby mode.

Specifically, these improvements translate to:

- A design allowing for quick disassembly of the main components of the battery,

- The removal of wiring harnesses to reduce the risk of failure,

- An optimized electronic system (Battery Management System) for better monitoring of the battery’s health status to prolong its lifespan,

- An optimized BMS (Battery Management System) power consumption, enabling the battery to be stored for over 12 months without recharge.

The mass production of this new battery does not signify the end of collaboration between the R&D teams of both companies: they continue joint research for even smarter, scalable, and environmentally friendly batteries. For example, developing an in-house electronic system for the battery will improve charging control to further extend its lifespan.

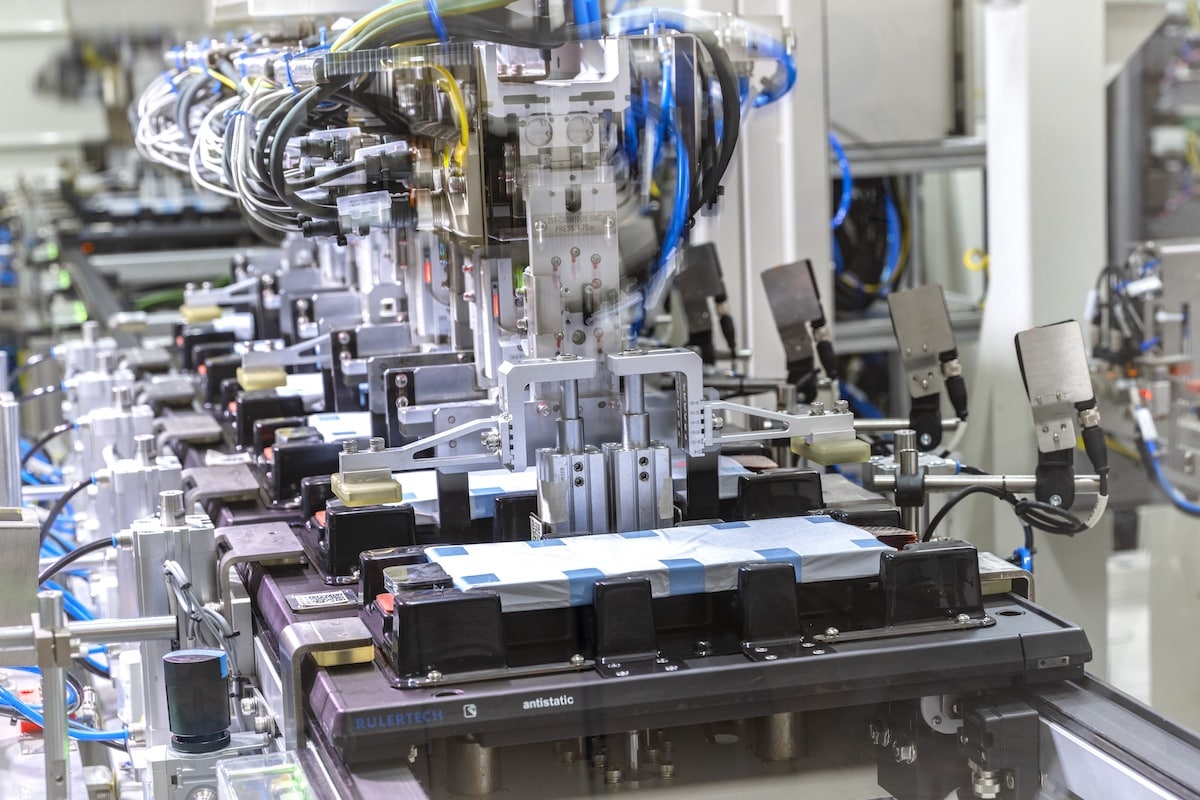

To ensure industrial production of this new battery, an automated assembly line will soon be installed at GCK Battery’s factory in Lempdes (Puy-de-Dôme), increasing capacity to 140,000 batteries per year. GCK Battery plans to hire an additional 15 people by 2026 to support this new activity.

Relocating its battery production will allow Fifteen to reduce manufacturing impact through cleaner energy, shorter transport distances, and better quality control. This eco-design approach and direct repair at the manufacturer’s site will enable 85% of defective batteries to be repaired. Overall, this will prevent 86 tCO2e emissions in the first year of battery production, thanks to their doubled lifespan (in charge cycles) and improved repair rates.

As a reminder, the carbon footprint of transporting a passenger over 1 km is 200g of CO2 equivalent for a conventional car, 130g for a diesel bus, and around 30g for a shared electric bike, depending on usage rates.

Fifteen, a French company leading active mobility for 15 years, is fully committed to a “Made in France” approach: currently, over 90% of its shared bike fleet is European-made, and since the launch of its assembly line in Auxi-le-Château (Pas-de-Calais) last May, all new Fifteen electric bikes are assembled in France.

By developing partnerships, expertise, and industrial tools in France, Fifteen is executing its relocation strategy and contributing to the growth of the bicycle sector across the country. With bike and station assembly, as well as component sourcing, Fifteen currently collaborates with around a dozen industrial actors in the Hauts-de-France, Pays de la Loire, Normandy, Bourgogne Franche-Comté, and Auvergne-Rhône-Alpes regions.

GCK Battery is a subsidiary of the GCK group, an expert in transportation decarbonization.

Employing 45 people, the company designs, develops, and manufactures lithium-ion batteries for various transport sectors (light mobility, automotive, maritime, and rail).

Compatible with all latest-generation Fifteen e-bikes, this new battery enables cities of all sizes to offer increasingly efficient services for decarbonizing mobility.

ALSO READ: NIU aims to democratize battery swapping

This page is translated from the original post "Fifteen et GCK, acteurs de la Réindustrialisation" in French.

We also suggestthese articles:

Also read