Refactory, the industrial garage of the future by Renault

Between car reconversion, retrofit, second life of batteries, and hydrogen, Refactory establishes the circular economy at Renault.

From past to future, this is the meaning of the Renaulution that the manufacturer aims to establish. One of the best illustrations is the reconversion of the Flins site (Yvelines). Formerly a factory for the star Clio, it is today dedicated to the ZOE and new innovative automotive recycling activities.

A second life for the car

Ensuring a second life for vehicles is more relevant than ever. The Renault group anticipated this trend at its Flins site, which takes on the challenge of the circular economy by extending the lifespan of cars. In addition to the production of the Zoe, this key factory in Renault’s electric strategy has launched into Refactory: vehicle reconditioning, recycling, reusing batteries, parts, and materials. As Clotilde Delbos, General Director of Mobilize, explains: “Flins had already decided to work on a number of spare parts, with lesser-known subsidiaries, but very advanced in recycling. We therefore decided to transform Flins to favor the circular economy (the vehicle, the battery, industrial recycling), starting slowly, then scaling to industrial levels.”

“We can thus promise a dealer to handle a used car and have it reconditioned and ready for delivery in a maximum of 10 days. Two days before its delivery to the dealership, a 360° view is conducted in studio to post the ad online, enabling immediate sale and delivery to the customer. It’s foolproof,” assures C. Delbos, “regarding Mobilize, since vehicles are never sold (see previous pages), this reconditioning strengthens the relevance of the economic model because each car can run longer, and worn parts retain residual value on the recycling market.”

Reconditioned Batteries

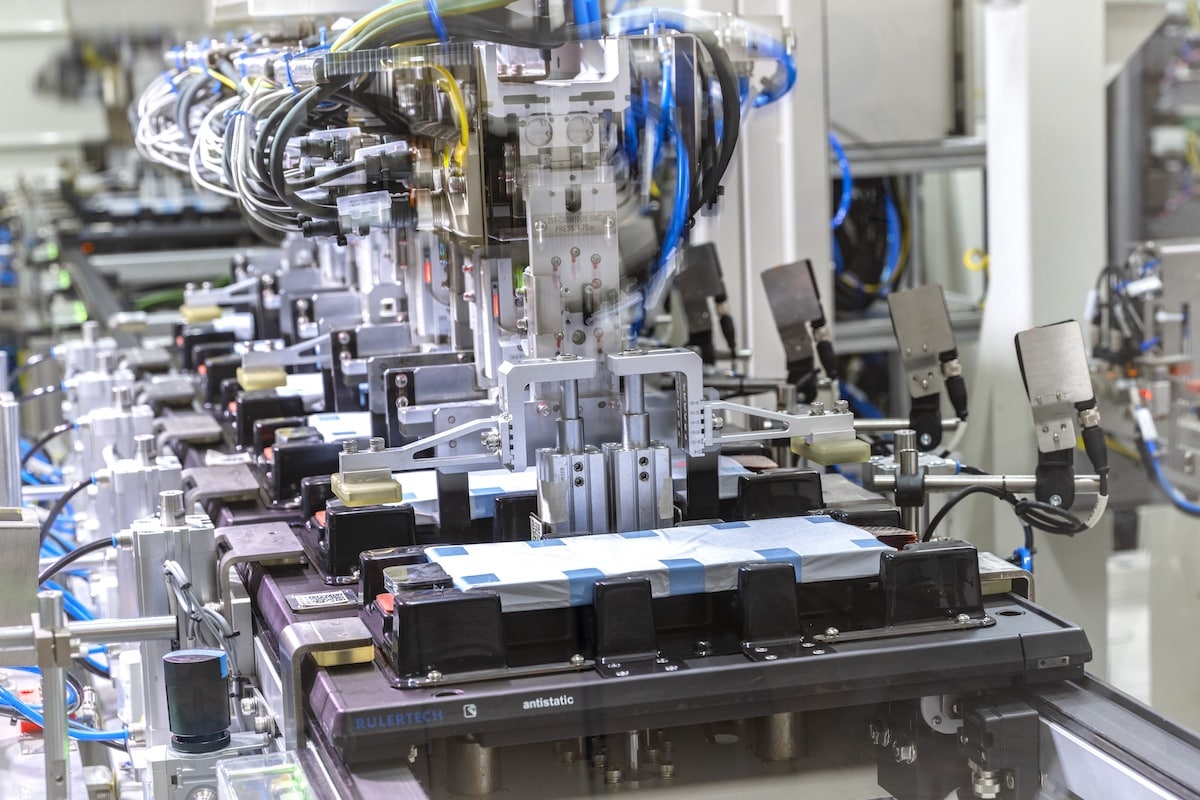

In September 2021, the first Refactory VO unit reconditioned used vehicles. This sector will continue with major repairs. Then, from 2023, a Re-Trofit section will enable conversion of thermal utility vehicles to electric. The third Re-Energy activity hub already continues an existing subsidiary. This is Gaia, specializing in the second life of batteries.

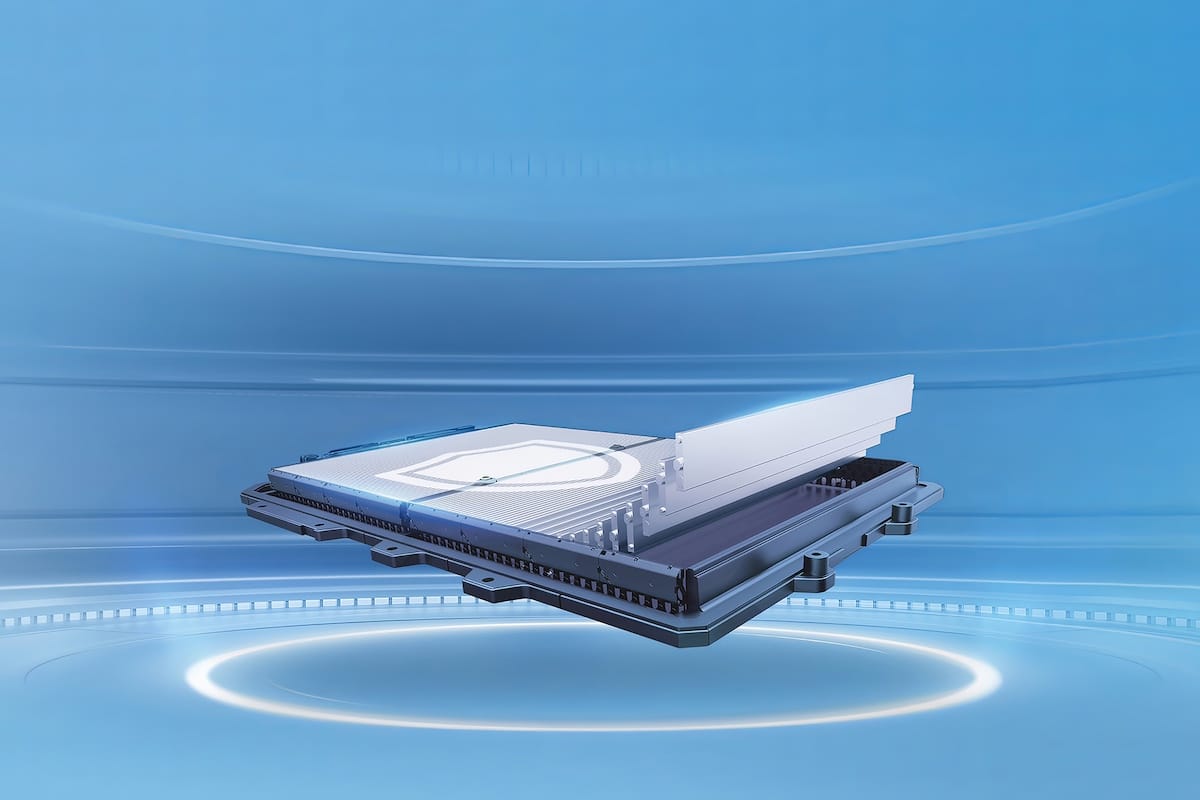

« Having a ten-year lead over our competitors in electric vehicles, when Renault launched ZOE in 2012, we were not assured about the battery lifespan, admits Mobilize’s head. That’s why Renault rented the batteries to reassure customers, hoping they would last 8 years. In the end, our teams realized that the battery lasts not just 8, but more than 10 years in its primary life, then 15 or even 25 years with a second life… and recycling at 95% gives the battery additional value. So, what to do with these batteries that we owned, considering we have sold 400,000 Zoes since 2012? We launched projects like Black Swan (the first passenger boat equipped with second-life batteries and fully electric in Paris, Ed.), energy storage on islands, but also 75 MWh in Flins, Douai, Sandouville, or Everligsten in Germany to send excess electricity back to the grid.”

What about the vehicle at end of life and its raw materials? “We obtain a reusable quality to remake batteries thus avoiding sourcing cobalt from Congo.”

A unit for hydrogen utility vehicles

Re-Energy will do more than just thermal and electric vehicles. The factory will contribute to the growth of the Hyvia subsidiary, assembling fuel cells, charging stations, and producing hydrogen for utility vehicles. The Flins Refactory will not be a one-off model. Renault plans to replicate it in several smaller sites across France and Europe. “For this to be a profitable activity, these units must be within 200 km of major urban centers,” adds Clotilde Delbos. A Re-Factory will thus open in Seville (Spain) by the end of 2022. This mini-site aims to recondition 10,000 vehicles and 1,000 batteries annually by 2025.

Finally, the last of the four Refactory hubs is an incubator dedicated to research and innovation in circular economy, professional training, prototyping utility vehicles, and an innovation center for “Industry 4.0“. Ambitious but coherent with the goal of better utilizing planetary resources, which are becoming increasingly scarce and expensive for both the manufacturer… and the customer.

Also read: Lithium: a battery factory in Alsace starting in 2025

This page is translated from the original post "Refactory, le garage industriel du futur par Renault" in French.

We also suggestthese articles:

Also read