How does an electric car work?

Now that electric cars are finally spreading on our streets, do we at least know how they work? No need to open the hood to check oil or water levels; everything is much simpler here. That doesn’t mean that the technology embedded in these machines isn’t reaching new heights.

Electric cars are not a recent invention. As early as the mid-19th century, it was already possible to buy a vehicle propelled exclusively by an electric motor. By the end of that century, electric cars were even setting major speed records at a time when internal combustion engine technology was still underdeveloped. However, a few years later, electric cars fell into obscurity: driven by the mastery and exploitation of fossil energies, the industrial revolution chose its side, and it was only at the end of the 20th century that we finally moved back towards electric propulsion vehicles. As the prospect of exhaustible natural resources and pollution problems—especially from the transportation industry—began to emerge, electric technology regained appeal in the eyes of manufacturers.

In the late 2000s, electric cars entered the lineup of major automakers: Nissan Leaf (2010), Mitsubishi i-Miev (2010), Renault Zoe (2012) finally offered viable alternatives to combustion models for urban use. And with the arrival of the juggernaut Tesla and its ingenious fast-charging network, electric cars became fully capable of long trips. Ten years later, they are now essential for all brands. By 2030, they are even expected to surpass fossil-fuel-powered cars in Europe. But by the way, how do they work?

A very simple mechanics and large batteries

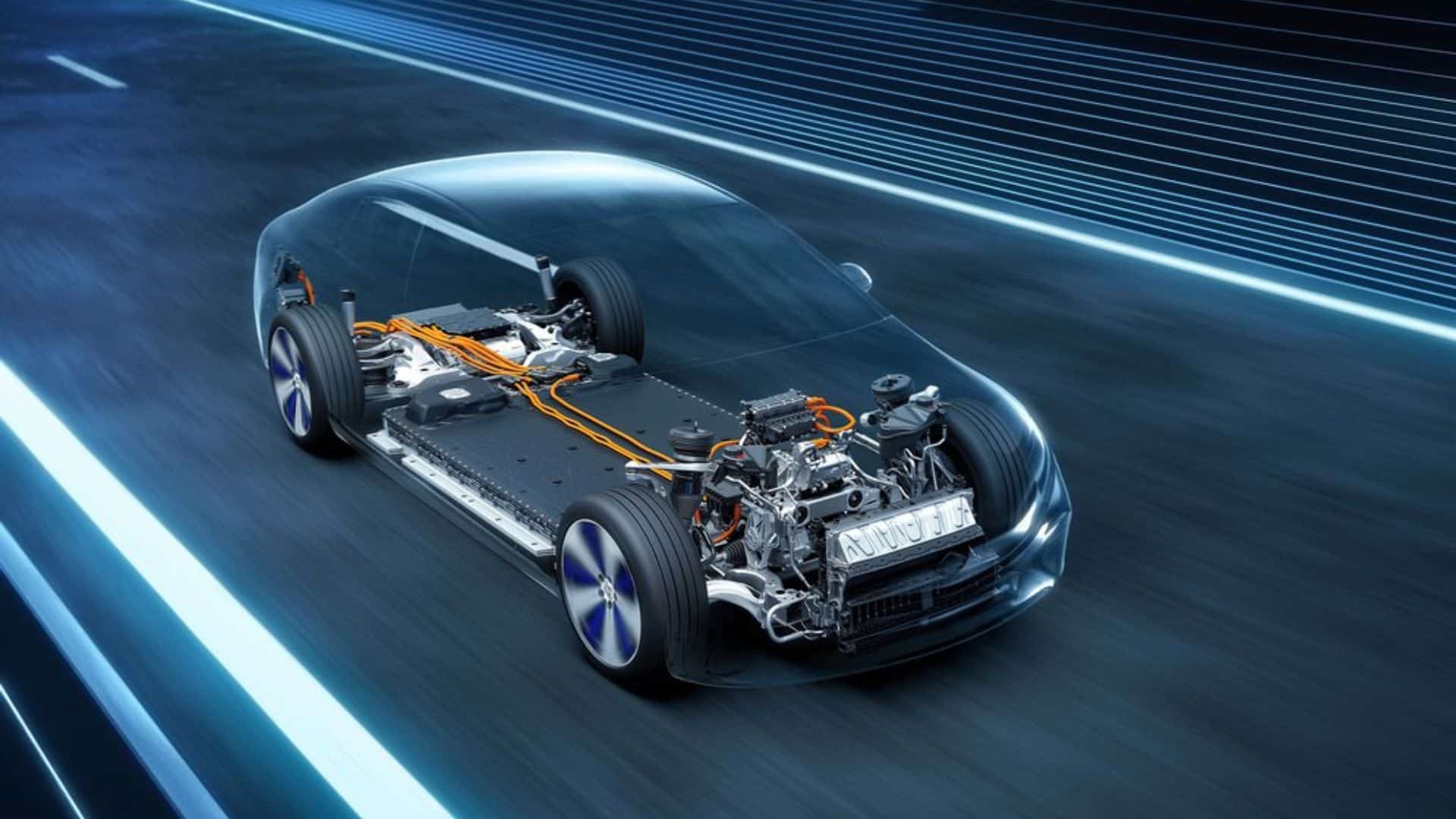

Instead of the principle of the explosion engine which has been widespread in the automotive world since the early 20th century, electric cars use a process that converts electrical energy into mechanical energy to propel the vehicle. Its motor has a rotor that moves within a stator thanks to the generation of a magnetic field. The rotor’s movement creates mechanical energy that drives the wheels. The direct current from the batteries is converted into alternating current before reaching the motor, and there are two types of motors: the most common synchronous motor (70% of the automotive market in 2020), found in most recent luxury and high-power models (Porsche Taycan, Audi e-tron GT, Kia EV6, Hyundai Ioniq 5…) or vehicles like the Peugeot e-208, and the asynchronous motor, which is more often used in lower-powered city cars. Some, like Tesla, combine these two motor types in one vehicle, each with its advantages and disadvantages. The asynchronous motor costs less to produce, is smaller, and offers better durability. The synchronous motor, on the other hand, has a higher efficiency but is more expensive and becomes more energy-consuming at highway speeds and high velocities (in all cases, an electric car consumes less city and low-speed driving, while a traditional combustion engine consumes less at steady highway speeds). Regarding performance, they can range from gentle city acceleration to terrifying launches in Tesla and Porsche Taycan models. It all comes down to software and electronic management of the batteries (and the chosen balance between energy consumption and performance).

Indeed, the central mechanical element of an electric car remains its battery. In 1995, the batteries of a Peugeot 106 electric did not exceed 12 kWh of capacity. Today, the batteries of a Peugeot e-208 reach 50 kWh, and the largest market models exceed 100 kWh. This battery capacity directly determines the maximum range, as well as the vehicle’s weight and price: the larger the batteries, the heavier and more expensive the car. It is the most sophisticated component of an electric vehicle, typically functioning according to the lithium-ion formula. Significantly improved over the last decade, this technology is expected to gradually give way to other systems that will increase range, reduce weight, and speed up charging.

Obviously, recharging remains a sensitive point on modern electric vehicles. It takes a long time on a standard alternating current socket (several days for a large electric car) and requires ultra-sophisticated fast-charging systems using direct current to avoid wasting too much travel time on highways (80% recharge in about half an hour via Tesla Superchargers and other Ionity stations, provided the vehicle can handle high charging power). Modern electric cars can also recharge at medium speed at home with a wall-mounted charger (“wallbox”) using alternating current, allowing a full recharge of a large battery in just one night.

Finally, it’s worth noting that thanks to their simple mechanics, electric cars are known to be more reliable than combustion vehicles and require less maintenance (no oil changes and other filter replacements…). Thanks to energy recovery, they also wear out their brakes less. Of course, the main drawback remains the purchase price, which is still generally higher than that of similar combustion models, especially for city cars.

Read also: CATL inaugurates its first rapid battery exchange stations

This page is translated from the original post "Comment fonctionne une voiture électrique ?" in French.

We also suggestthese articles:

Also read