BMW takes a major step forward in its industrial transformation

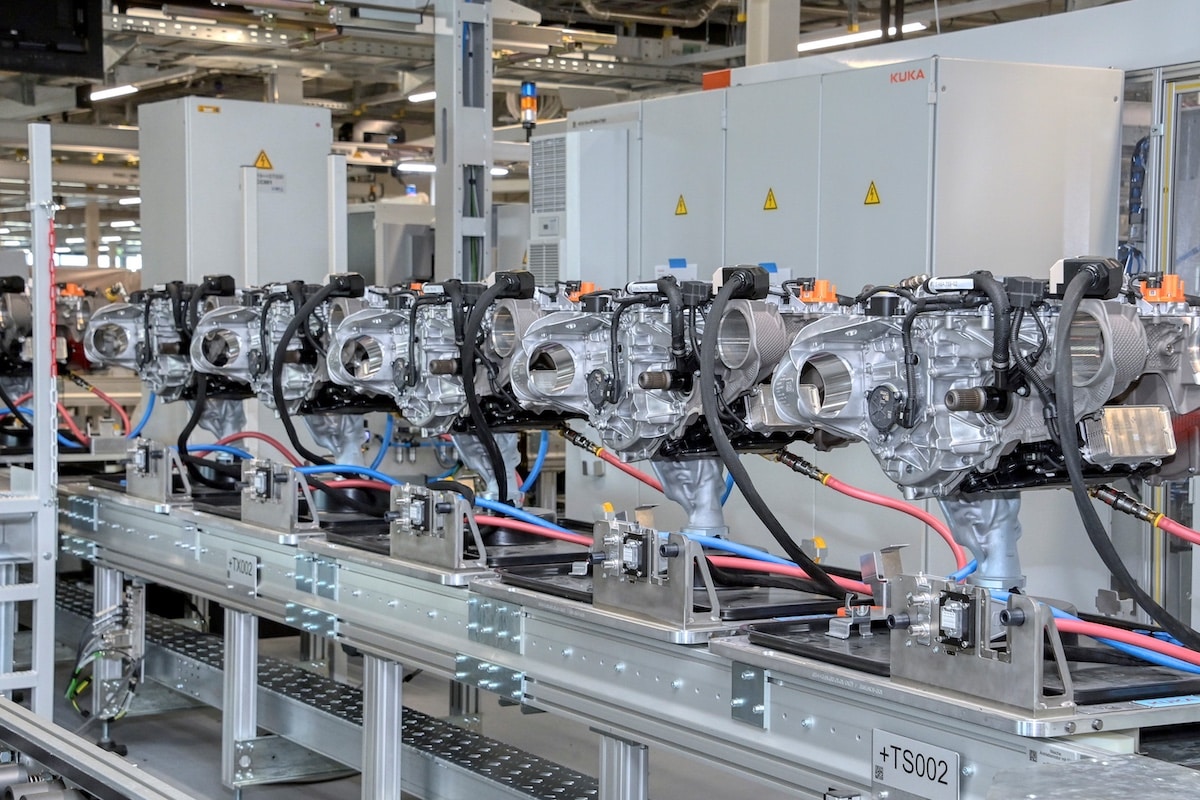

In Steyr, Austria, BMW has officially launched the series production of its new generation of electric motors.

These latest generation units are intended to equip the models of the future BMW Neue Klasse lineup. For the first time, the historic factory, which has long specialized in combustion engines, is now assembling 100% electric powertrains.

“Today, we are laying the groundwork for the future of the BMW Group,” said Milan Nedeljković, a board member in charge of production. With the sixth-generation electric motor (Gen6), Steyr becomes a central pillar in the industrial deployment of BMW’s electric strategy.

For over 40 years, the Steyr plant has produced combustion engines for BMW and MINI. Now, it is turning towards electrification with monumental investments: more than one billion euros will be injected by 2030 to develop the production and engineering skills necessary for electric powertrains. Nevertheless, technological openness remains a priority: Steyr will continue to produce gasoline and diesel engines alongside.

“Technological diversity is our strength. It provides us with the flexibility needed to ensure long-term jobs,” emphasizes Klaus von Moltke, the plant director. By 2030, half of the workforce could be dedicated to electromobility.

Lighter, More Efficient, More Performance

The rotor, stator, transmission, and power converter of the Gen6 motor are assembled on-site, with key components like the housings coming from the Landshut plant. The converter, the system’s true “brain,” now uses 800-volt technology and silicon carbide semiconductors, ensuring superior efficiency.

This modular architecture allows for great industrial flexibility: the same lines will be able to produce different variants of the Gen6 motor according to the needs of the Neue Klasse, streamlining costs and volumes.

You might be interestedin this article:

Compared to the previous generation (Gen5), the new motor shows a 40% reduction in energy losses, a 20% decrease in manufacturing costs, and a 10% reduction in weight. The result: an overall improved energy efficiency of 20%, contributing to a range of up to 800 km WLTP for the future iX3.

Thus, BMW is transforming its mechanical heritage into a technological springboard. And with Steyr at the forefront, the Neue Klasse marks a new era for the brand with the propeller.

ALSO READ: Aside from the ugly paint, what do you think of the new BMW?

This page is translated from the original post "BMW franchit une étape décisive dans sa transformation industrielle" in French.

We also suggestthese articles:

Also read