Volkswagen: First Battery Factory in 2024

After years of dependence on Asian suppliers, Volkswagen is launching its first battery factory in Salzgitter, Germany.

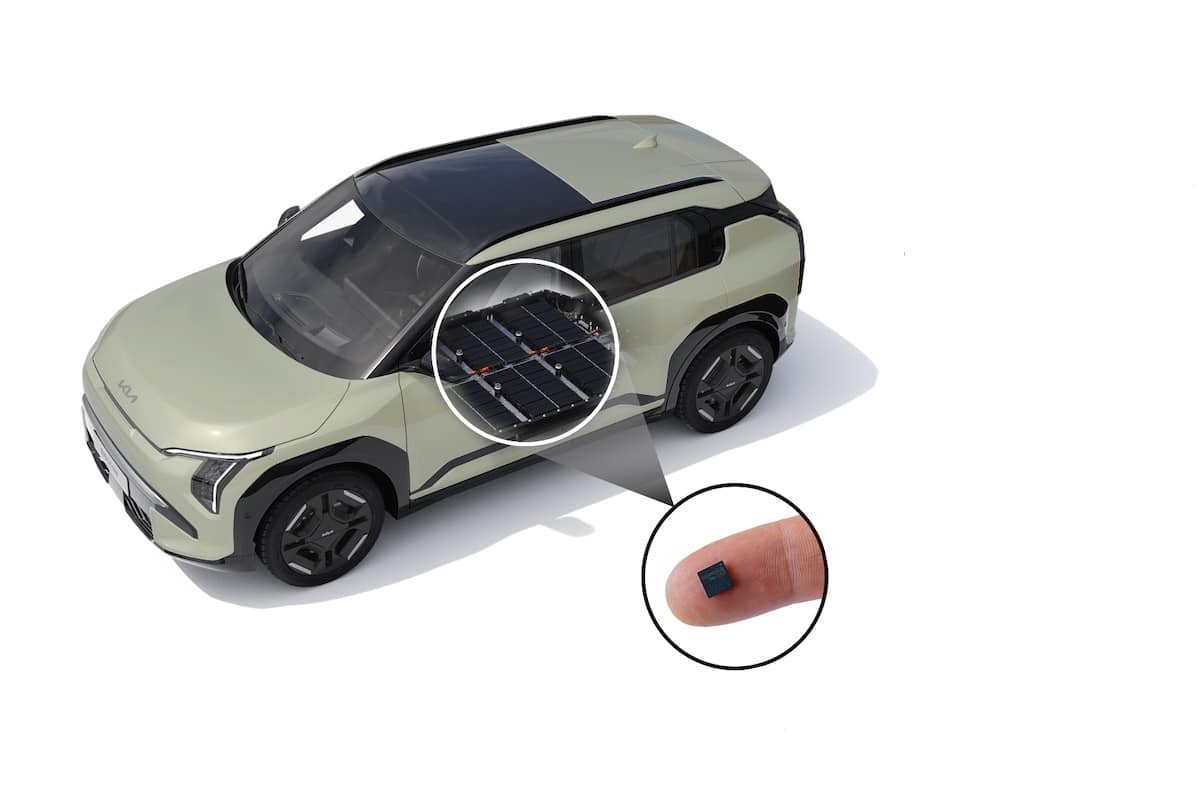

Since 2013 and the first electric Volkswagen e-Golf and e-up!, the automotive group has entrusted its batteries to suppliers. Not inherently a problem, but a dependency on Asian players like CATL, LG Chem, SK innovation, or Samsung SDI.

Volkswagen’s First Battery Factory

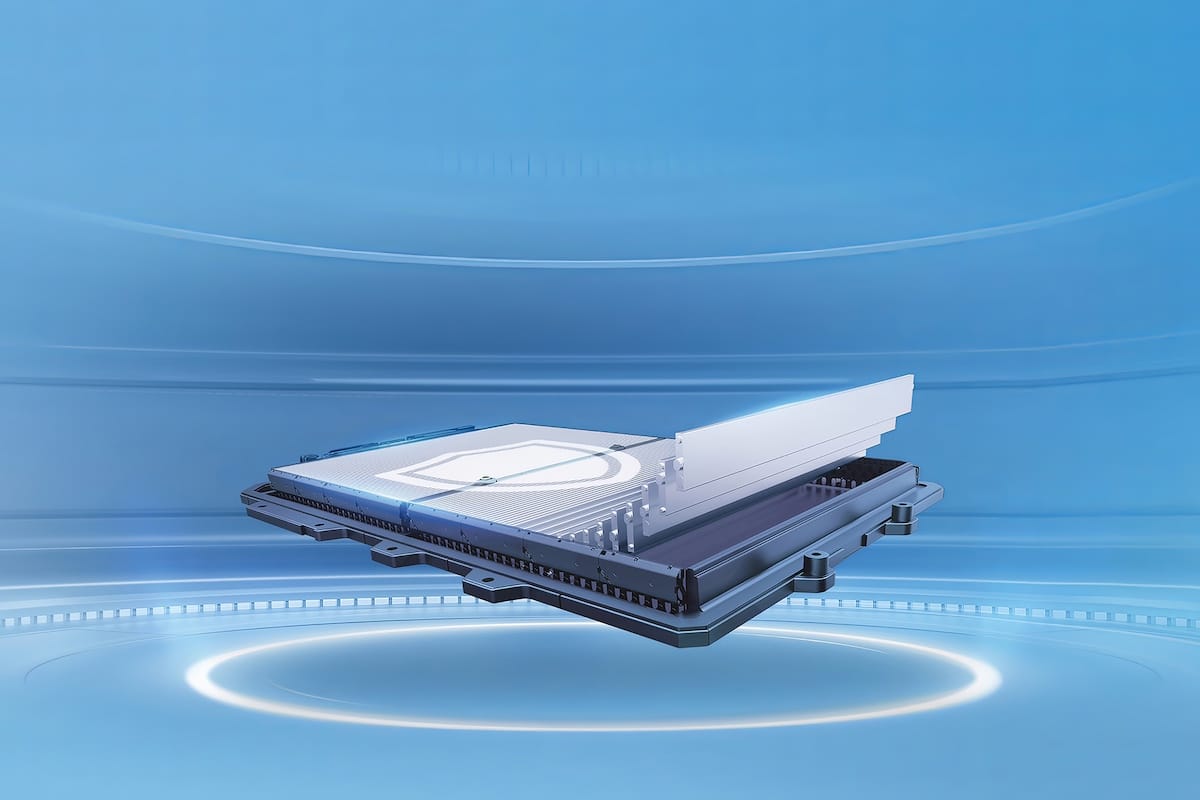

To regain control over the electric vehicle supply chain, Volkswagen has decided to build its own batteries. Last year, the German group already made a move by announcing co-production with the Swedish company Northvolt. The manufacturer has thus created a new company, PowerCo, headed by CEO Frank Blome.

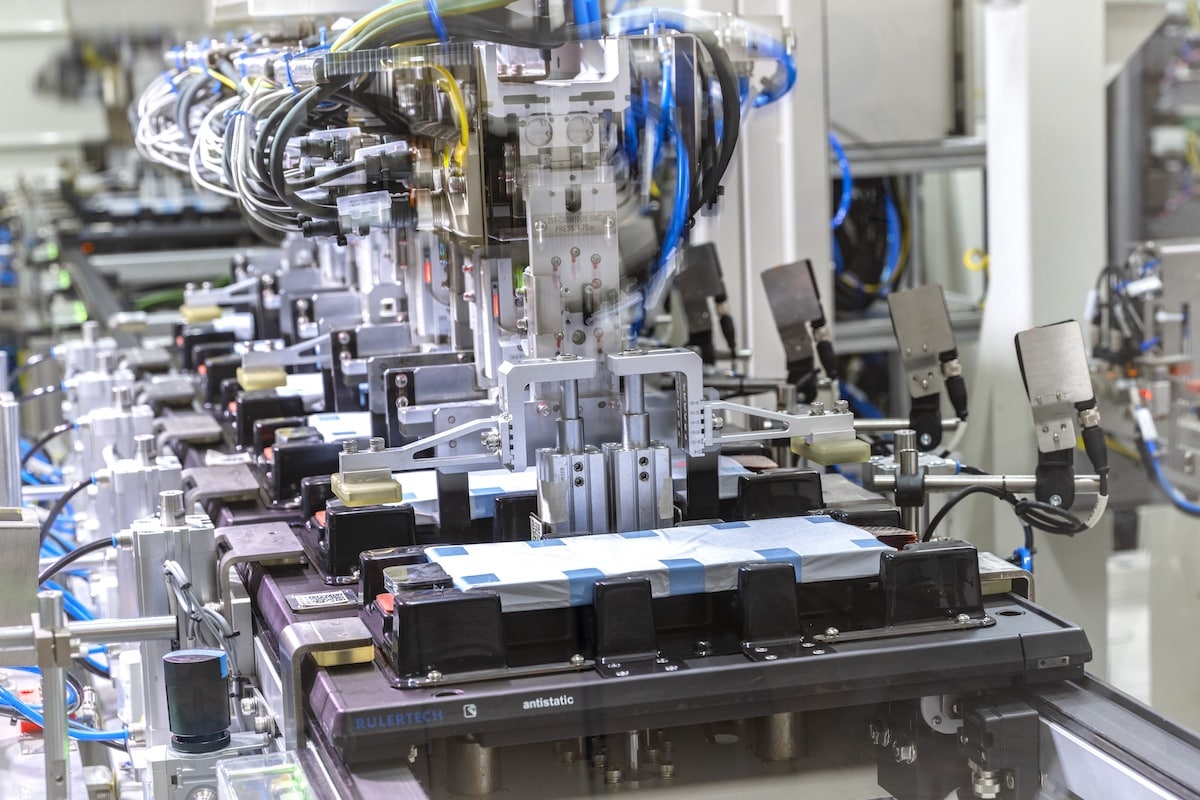

The new battery plant, nicknamed “SalzGiga,” is a 100% VW product. As the name suggests, it is located in Salzgitter, Germany. The site is as large as 30 football fields and will produce 40 GWh of batteries annually, enough for about 500,000 vehicles (averaging 80 kWh each).

“Today is a great day for the automotive industry in Germany and Europe,” declares German Chancellor Olaf Scholz at the event, “Volkswagen demonstrates what the future sustainable and environmentally friendly mobility will look like.”

Batteries for Half a Million Cars

Adjacent to the Salzgitter site, which already manufactures engines and is close to steel producer Salzgitter AG, the plant won’t start immediately. As shown in the images, construction is still ongoing, having started in 2020 and expected to end in 2024. The project costs about 20 billion euros but should generate a revenue of 20 billion euros per year in the long run. The Salzgitter plant will create 5,000 direct jobs and 20,000 jobs overall.

By 2030, Volkswagen will have six battery factories in Europe, with an annual capacity of 240 GWh. The second will, for example, be built in Valencia (Spain).

Read also: Test drive of Volkswagen ID.5 GTX: an electrifying SUV?

After a quick calculation, these batteries will supply over 3 million electric cars per year. By comparison, the manufacturer sold 2.44 million vehicles in Europe in 2021 across all powertrains.

Battery Recycling Also

The Volkswagen site in Salzgitter is more than ever becoming the battery hub. It also hosts the research center dedicated to this field. The company is developing its future chemistries and technologies there, as well as material recycling for future batteries. “Our goal is to create our own circular process in which more than 90% of each of our batteries is recycled,” declares Thomas Tiedje, head of technical planning at Volkswagen Components.

Rather than a pyrometallurgical process—burning everything in a furnace—Volkswagen prefers the LithoRec method. It is mechanical, involving dismantling to recover aluminum, copper, and plastics, followed by grinding and sieving to produce a powder. This powder contains the well-known lithium, cobalt, nickel, and manganese, which are sorted using solvents.

This page is translated from the original post "Volkswagen : première usine de batteries en 2024" in French.

We also suggestthese articles:

Also read