Jean Fourche and Gouach: When the Bicycle Industry Recycles Itself (Interview)

On one hand, Jean Fourche wants to create a practical city bike. On the other, Gouach is rethinking the battery ecosystem. Together, these two companies aim to relocalize e-bikes in France, while making them accessible with the “Jean Foudre.” A jointly conducted interview with co-founders Benoît Maurin and Alexandre Vallette.

What is Jean Fourche’s journey? You first launched a muscular bike, but not an entirely conventional one either?

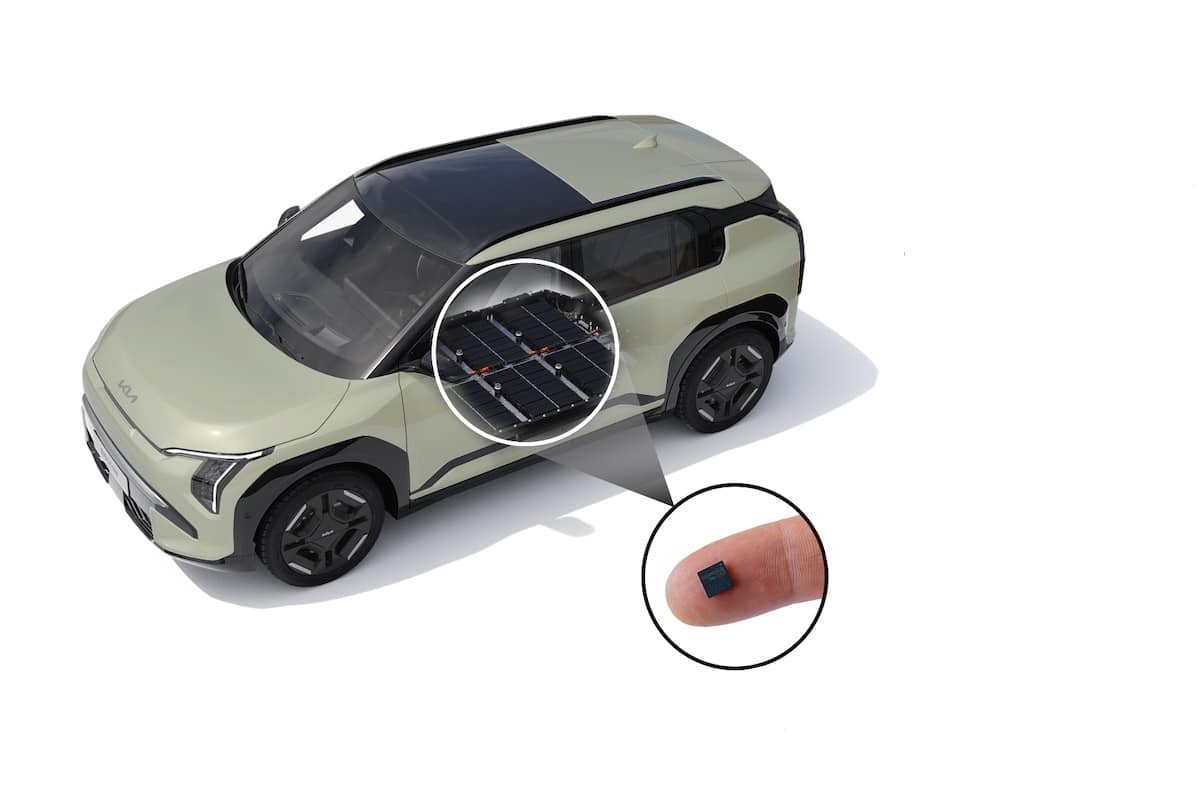

Benoît Maurin: It all started with three friends, meeting in a participatory bike repair workshop focused on durable, repairable products. We wanted to create a more sustainable bike brand, manufactured locally, inspired by the nostalgic question about the bike industry’s offshoring in the 1990s. Our first bike is unisex, suitable for all sizes, combining features of cargo and city bikes. But for a year and a half, people have been asking for an electric bike. However, we didn’t want to electrify with the systems identified two years ago. Here, we see that with companies like Gouach (batteries) or Virvolt (motors), we can offer bikes that are both electric and designed for easy replacement or obsolescence management. Also, we didn’t design a specific frame for the electric version. We outsourced the electrical part, allowing customers to “de-electrify” their bike at any time.

Besides the frame from Portugal, what aspects of the “Made in France or Europe” label are present in this new Jean Fourche electric bike?

B. M.: About 80% of our components come from Europe, and ideally, from France. To keep it simple, we could have bought a Chinese kit with a hub motor and cadence or speed sensors, plus Chinese batteries. That would be cheaper but less quality. We wanted recycled and infinitely recyclable batteries; it’s fortunate to have Gouach nearby in Bordeaux and France. Yes, we want to develop an electric bike, but under specific conditions, working with a company that creates value in France.

Regarding Gouach, where did the idea of recyclable and repairable batteries originate?

Alexandre Valette: Gouach was founded four years ago. I started alone, then with friends, initially studying batteries that were being discarded. We collected hundreds of batteries and analyzed all the cells. All batteries contain standard cells—if one doesn’t work, 80% of them are still in good condition. This observation launched our journey to create eco-designed batteries, meant to facilitate cell replacement—like a remote control where you don’t throw it away when it stops working. You just change the battery, but it’s not so simple given higher currents and the more hazardous chemistry of batteries today.

We developed the most functional approach possible through numerous patents, adding a connected aspect that allows non-experts to perform maintenance and diagnostics. Integration is also straightforward, as bikes use very different communication protocols via the motor and batteries, allowing updates without opening the battery.

If I understand correctly, these batteries are also recycled? And where do you source them?

A. V.: Yes, we continue the process by collecting batteries that would otherwise be destroyed, then reconditioned. We are thus half recycler, half manufacturer, with an environmental impact reduced by a factor of four compared to standard batteries. Most come from Europe and France—mainly fleets with battery issues or recyclers that are costly to pay—I conduct an audit of the stock and set prices accordingly.

Does producing in France make your batteries more expensive?

A. V.: Initially, our goal was to produce in France on a small scale. As we scale to hundreds of thousands of batteries, we will achieve significant economies of scale, which means our batch-produced batteries with new cells could be more expensive. Using reconditioned cells puts the price on par with Asian batteries. Plus, it’s more environmentally virtuous, repairs easily, and connects seamlessly. Our role is to demonstrate that this is the right long-term choice.

B. M.: The lifecycle is important because repairability matters. By 2025, we could see a wave of e-bike batteries being discarded, with many costing around €500—about a third or a quarter of the bike’s total value—that will need proper disposal. We are considering how to promote more sustainable use over longer periods. We look beyond five years—we are projecting 10 or even 20 years of use.

At Jean Fourche, how far along are you in the “Made in France” concept, and how do you plan to improve it? Are new models on the horizon?

B. M.: Currently, we source as much as possible within Europe and France, but we’re not going to dive into it blindly. There’s a growing trend toward relocalization, industries like aerospace and automotive are struggling and starting to invest in soft mobility. We aim to source locally as much as possible through this shift. In ten years, the cycling industry in France will be very different. In the short term, we’re already exploring the possibility of manufacturing our frames in Nouvelle-Aquitaine. After our “Jean Foudre” (the nickname for the electric model), which will be available in April, we plan to work in 2023 on a cargo bike designed for family and professional use. We can’t say much more yet, as we’re still working on the design, but Gouach will be involved in this project as well.

And at Gouach, what are your main challenges for the coming years? Are you planning to work on other mobility sectors or industries?

A. V.: We receive many requests, not only for mobility but mainly for bikes. We are exploring other possibilities in industry and electricity storage. Our added value is the ability to replace worn-out elements in cells. For example, a cell for Jean Fourche is best sourced due to its high energy density. After two years, it will have only 70% capacity left, which is not enough to guarantee initial autonomy. Therefore, we remove them from batteries, giving them a second life for stationary applications, maximizing their potential.

Gouach: Company co-founded in 2019 by Alexandre Vallette, Maël Primet, and Maxime Agor, specializing in manufacturing recycled, recyclable, and repairable batteries near Bordeaux, supplying initially several brands of electric bikes and scooters (Jean Fourche, Plume, Gaya, Lime, Pony, etc). Jean Fourche: Company co-founded in 2019 by Benoît Maurin, Mathieu Courtois, and Maël Le Borgne, assembling muscular and electric bikes in Bordeaux.

This page is translated from the original post "Jean Fourche et Gouach : quand l’industrie du vélo se re-cycle (Interview)" in French.

We also suggestthese articles:

Also read