Mercedes proves that batteries are recyclable

Mercedes becomes the first car manufacturer to complete the battery recycling chain with its own factory.

One by one, the clichés about electric mobility are collapsing like a house of cards, and Mercedes continues to contribute to the effort. We remember the crash test between two 100% electric vehicles which proved that battery-powered cars are no more dangerous than their internal combustion engine counterparts in the event of an accident. The star manufacturer has now opened the first battery recycling plant equipped with an integrated mechanical and hydrometallurgical processing system in Kuppenheim, in southern Germany, to integrate electric mobility into a virtuous global process.

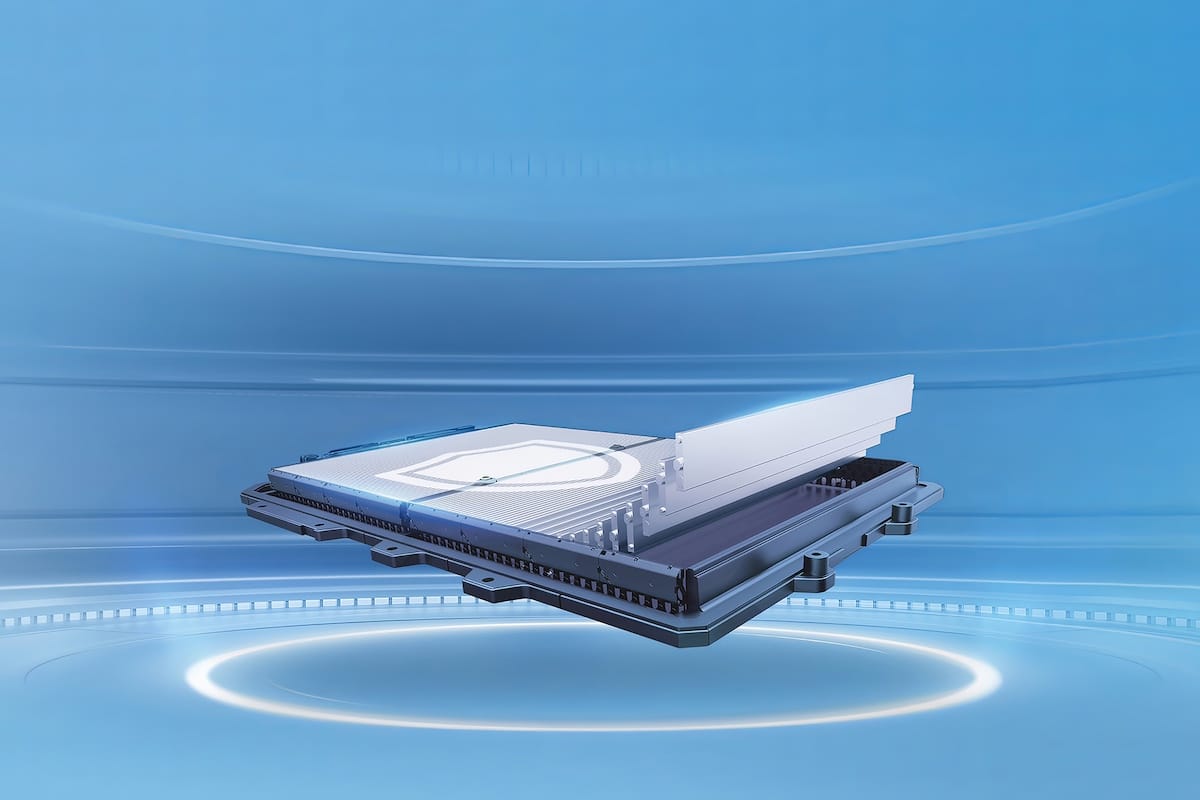

The expected recovery rate is over 96%. Precious and rare raw materials such as lithium, nickel, and cobalt can thus be recovered and reused in new batteries. Mercedes has invested several tens of millions of euros in the construction of the new recycling plant.

Mercedes in a holistic approach

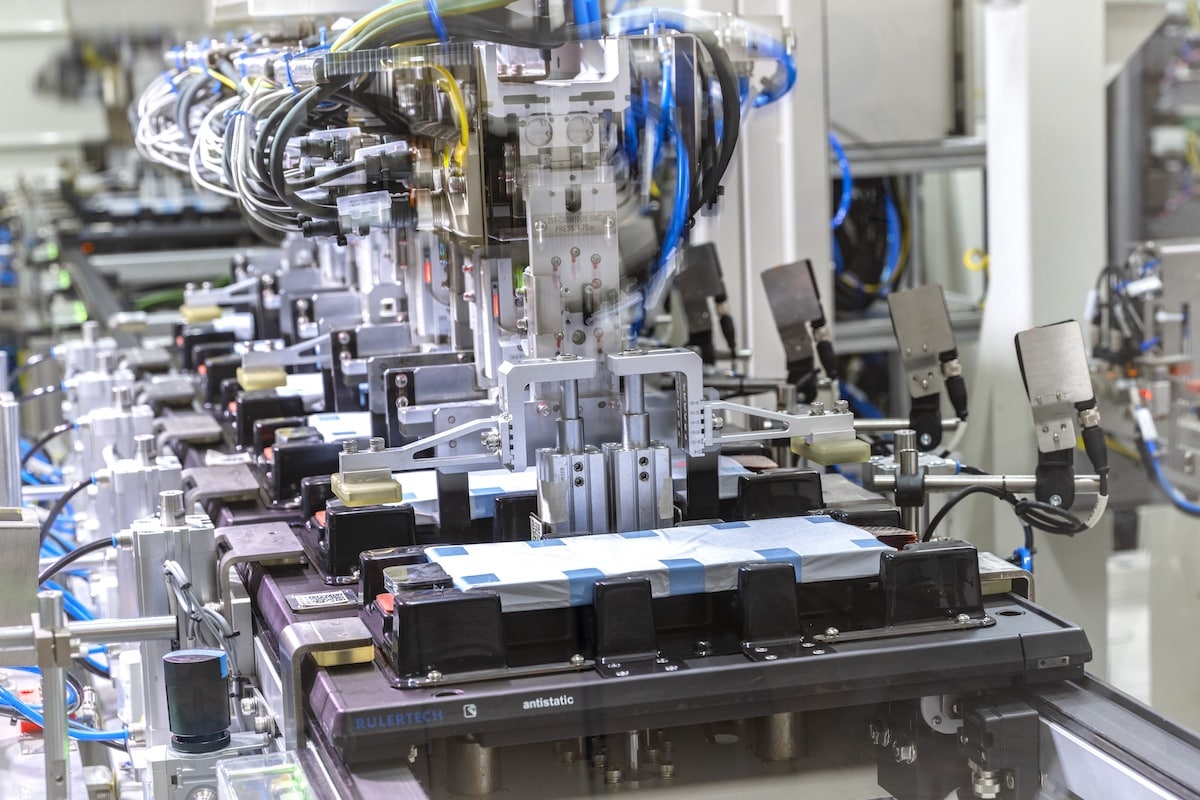

The process set up in this ultra-modern facility covers all steps, from shredding battery modules to drying and treating materials. Once plastics, copper, aluminum, and iron are sorted and separated, precious metals are extracted individually in a multi-step chemical process. Once processed, these recycled materials can be reintroduced into a standard battery manufacturing chain to produce new cells.

It certainly requires energy to achieve such results, and using non-green electricity would make absolutely no sense, except to provide arguments to anti-EV proponents. The Mercedes factory operates in a carbon-neutral manner, as it is powered 100% by green electricity. The roof surface of the building, covering 6,800 square meters, is equipped with a photovoltaic system with a capacity of over 350 kilowatts.

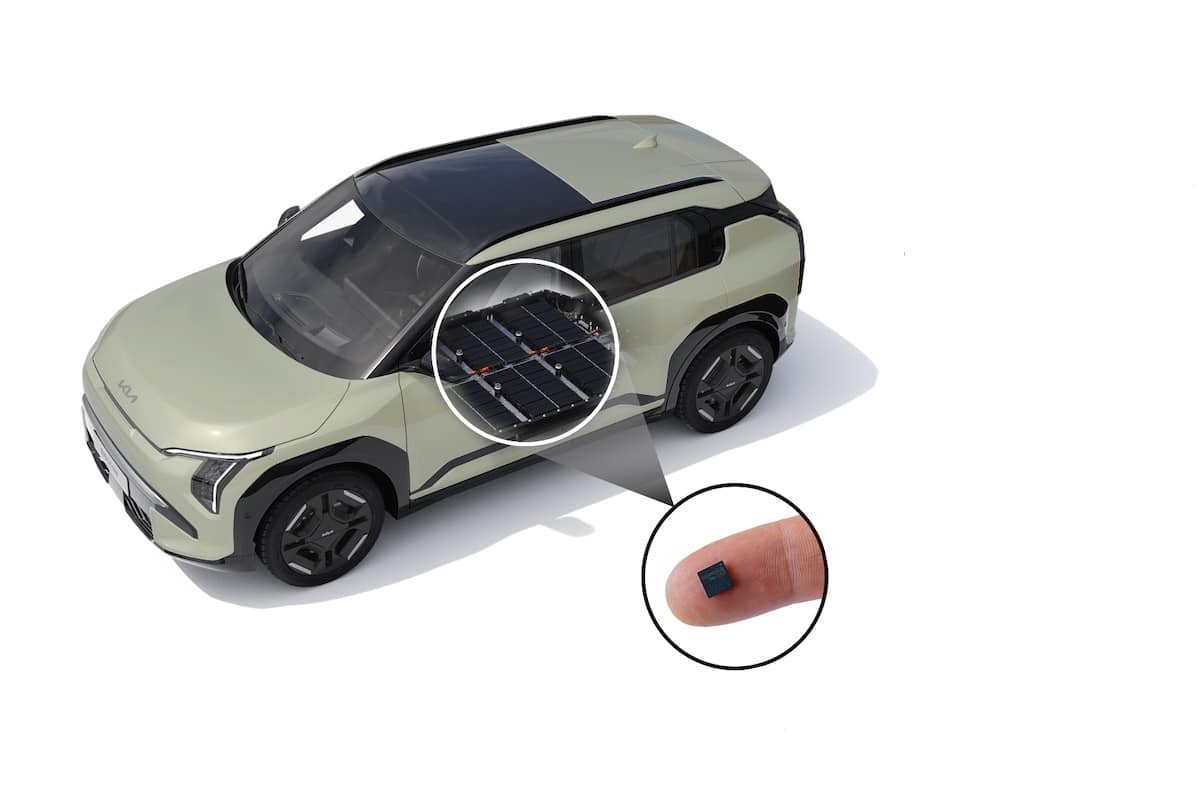

This factory has an annual capacity of 2,500 tons, and the recovered materials go into the production of more than 50,000 battery modules for new models. These production volumes are, of course, expected to increase in the medium and long term, and in a concern for resource preservation, Mercedes will offer refurbished batteries as spare parts for all its electric vehicles.

This page is translated from the original post "Mercedes prouve que les batteries sont recyclables" in French.

We also suggestthese articles:

Also read