Cheaper and lighter batteries—what a good idea!

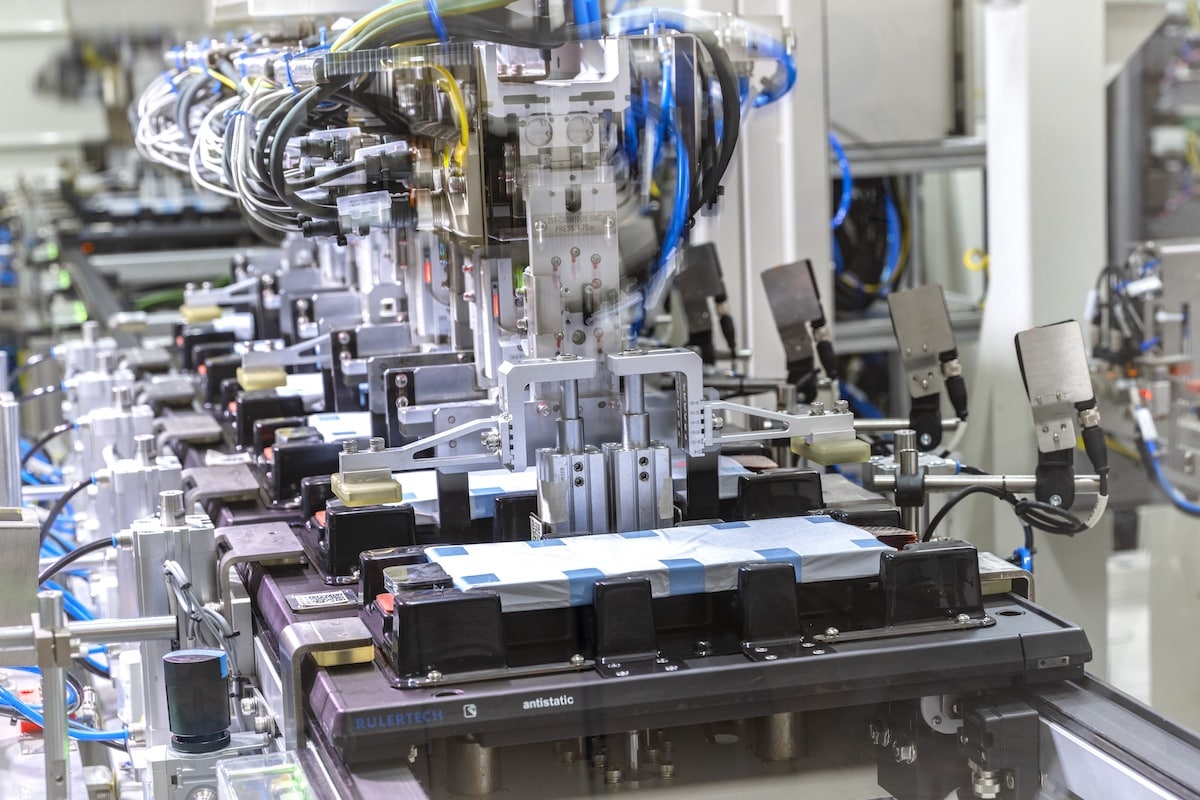

Stellantis and Zeta partner to develop a much lighter battery pack while maintaining the same usable energy.

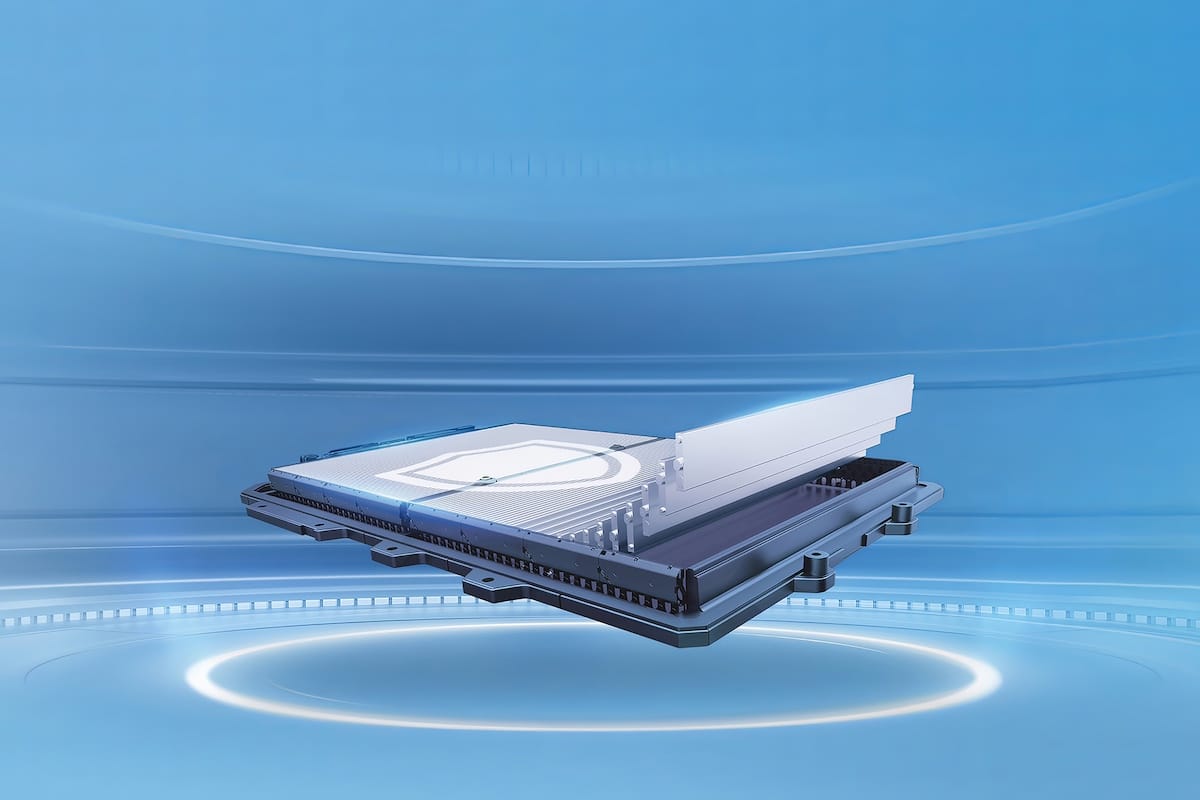

After focusing on battery range, the automotive ecosystem finally seems to realize that weight is a much more important factor. A lighter battery is simply better in terms of performance, reliability, and range. This improves the power-to-weight ratio, allowing the engine to deliver better acceleration and providing a more dynamic and responsive driving experience. This weight reduction also optimizes handling, braking, and energy consumption by reducing inertia-related losses. Mechanically, a lighter vehicle imposes less strain on the brakes, suspension, and tires, thus reducing component wear and enhancing reliability. Lightweight batteries, often more compact, generate less heat, which limits overheating risks and extends the lifespan of electrical systems.

In terms of range, weight is a crucial factor for electric cars: a lighter battery consumes less energy to move the vehicle, increasing energy efficiency. This reduction in mass also allows for better load distribution, improving aerodynamics and rolling resistance, which translates into increased range without increasing energy capacity. Finally, these improvements are part of a global trend to optimize vehicles to make them more performant, reliable, and suited to modern needs. Lightweight batteries thus remain a major challenge for manufacturers seeking to meet driver expectations regarding efficiency and sustainability.

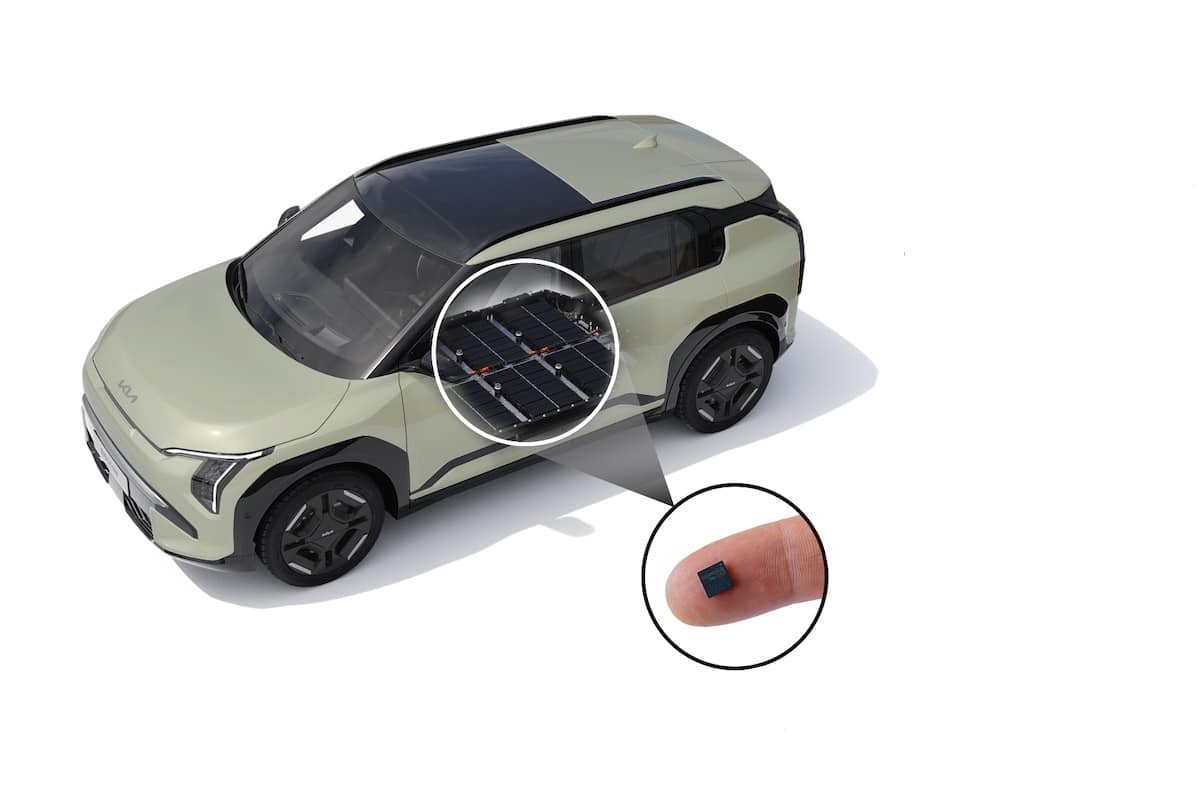

Stellantis and Zeta Energy announced a partnership to develop revolutionary lithium-sulfur batteries. These batteries promise an exceptional gravimetric energy density and performance comparable to current lithium-ion batteries but with significantly reduced weight. This could offer customers lighter vehicles with increased range, better handling, and recharge times up to 50% faster.

The lithium-sulfur technology, produced from recycled materials and methane, reduces CO2 emissions and manufacturing costs by half compared to lithium-ion batteries. These batteries do not use cobalt, graphite, manganese, or nickel, thereby simplifying the supply chain and lowering risks.

This project, integrated into existing gigafactories, aligns with Stellantis’ Dare Forward 2030 plan, which foresees 75 electric models. The first batteries should be used in their vehicles by 2030.

READ ALSO: Carlos Tavares, the pilot CEO loses his steering wheel

This page is translated from the original post "Des batteries moins chères et plus légères quelle bonne idée !" in French.

We also suggestthese articles:

Also read